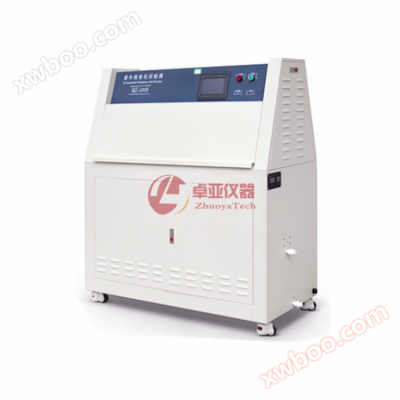

ZY-340BUV weather resistance testing machine

1、 Overview

This product uses a fluorescent UV lamp that best simulates the UV spectrum in sunlight, and combines temperature control, humidity supply, and other devices to simulate factors such as high temperature, high humidity, condensation, and dark rain cycles caused by sunlight (UV) that can cause color change, brightness, intensity decrease, cracking, peeling, powdering, oxidation, and other damage to materials. At the same time, the synergistic effect between UV light and moisture weakens or fails the material's single light resistance or single moisture resistance, making it widely used for evaluating the material's weather resistance performance. The equipment provides the best sunlight UV simulation, has low maintenance costs, is easy to use, adopts automatic control operation, high automation of the test cycle, good light stability, and high reproducibility of test results.

Compliant with standards:

GB/T14552-2008In the "National Standard of the People's Republic of China - Plastic, Coating, and Rubber Materials for Mechanical Industry Products - Accelerated Test Method for Artificial Climate", section a is the fluorescent ultraviolet/condensation test method.

GB/T16422.3-1997 GB/T16585-96Related analysis methods.

GB/T16585-1996National Standard of the People's Republic of China - Test Method for Artificial Climate Aging of Vulcanized Rubber (Fluorescent UV Lamp).

GB/T16422.3-1997Design and manufacturing standards for corresponding standard clauses such as "Plastic Laboratory Light Source Exposure Test Method".

Compliant with international testing standards: ASTM D4329、D499、D4587、D5208、G154、G53、ISO 4892-3、ISO 11507、EN534 prEN 1062-4、BS 2782; Current UV aging test standards such as JIS D0205 and SAE J2020.

2、 Structural material manufacturing

1Test box space: 400 × 1140 × 390

2Dimensions: 500 × 1300 × 1360

3Unit material: Internal and external 304 stainless steel

4Sample holder: Aluminum alloy frame type base frame visual panel

5Controller: Color touch screen programmable controller or RKC intelligent controller

6Radiation tube: 8 UVA-340 tubes, 4 tubes per side for a total of 2 sides

7Can be connected bidirectionally (RS232 communication interface)

8Power supply residual current circuit breaker control circuit overload short circuit alarm, over temperature alarm, water shortage protection

3、 Technical parameters

1Temperature range: RT+10 ℃~70 ℃

2Humidity range: ≥ 90% RH

3Temperature uniformity: ± 1 ℃

4Temperature fluctuation: ± 0.5 ℃

5Center distance inside the lamp tube: 70mm

6The center distance between the test sample and the lamp tube is 50 ± 3mm

7Irradiance: 1.0W/m2Internally adjustable

8The testing cycle for illumination, condensation, and spraying can be adjusted

9Lamp tube: L=1200/40W, 8 pieces (UVA service life of over 1600h)

10Control instrument: RKC intelligent controller

11Temperature control method: PID self-tuning SSR control

12Standard specimen size: 75 × 290mm (special specifications need to be specified in the contract)

13Sink depth: 25mm automatic control

14Effective irradiation area: 1020 × 290mm

15Ultraviolet wavelength: UVA range is 315-400nm;

16Test time: 0~999H (adjustable)

17Radiation blackboard temperature: 10 ℃~70 ℃

18Standard sample rack: 24 sets

19The unit has automatic spraying function

4、 Structural description

1The box is made of CNC equipment, with advanced technology, smooth lines, and beautiful appearance

2The material of the box is 1.2mm thick 304SUS high-grade stainless steel

3The air duct inside the box adopts a single circulation system, with an imported axial flow fan, which improves the air flow brightness and heating capacity, and significantly improves the temperature uniformity inside the test box

4Lamp tube: dedicated UV lamp tube, two rows of 8 tubes in total, 40W/tube

5Lamp lifespan: over 1600h

6Water source and consumption: about 8 liters/day of tap water or distilled water

7Install a total of 8 UVA ultraviolet lamps on both sides of the studio

8The heating method is an inner tank sink type heating, with fast heating and uniform temperature distribution

9The lid of the box is a double-sided flip cover, which can be easily and freely closed

10Automatic replenishment of water level in the inner tank to prevent damage caused by empty burning of the heating tube

11The sample holder is made of stainless steel or aluminum alloy

12The bottom of the unit is fixed with high-quality PU movable wheels

13The drainage system uses a U-shaped sedimentation device for drainage

14The surface of the test sample is parallel to the plane of the ultraviolet lamp

15The sprinkler system is equipped with automatic nozzles and adjustable water pressure inside

5、 Safety protection device

1Grounding protection

2Power overload short-circuit circuit breaker

3Control circuit overload and short-circuit fuse

4Water shortage protection

5Over temperature protection

6、 Temperature control

UVThe first-order optical reaction is not sensitive to temperature changes, however, the speed of the second-order reaction that follows is closely related to temperature changes. Generally speaking, as the temperature increases, the reaction rate will accelerate. Therefore, in the UV exposure test process, temperature control becomes important. More importantly, it is necessary to match the test temperature used in the accelerated test with the highest temperature encountered by the material in practical applications. The temperature during the UV process in the device is set to any point between 50 ℃ and 70 ℃, depending on the level of illumination and indoor ambient temperature. The temperature regulation of the equipment is controlled by a controller with microcomputer calculation function to command a series of systems such as air heaters and water heaters inside the equipment.

Moisture: As the temperature increases, the destructive power of moisture on materials will sharply increase. Therefore, temperature control is the most basic requirement in humid environments. Furthermore, to achieve an acceleration effect, it is necessary to maintain a high temperature environment during the humid process. So the temperature during the condensation process is set to any point between 40 ℃ and 60 ℃.

7、 Heating system

1Adopting U-shaped titanium alloy high-speed heating electric heating tube

2Temperature control and lighting are completely independent systems

3The temperature control output power is calculated by a microcomputer to achieve high-precision and high-efficiency electricity efficiency

4The heating system has an anti overheating function:

1)The blackboard temperature is controlled by a color touch screen programmable controller or a digital key temperature controller for heating, and the output power is calculated by a microcomputer with PID self-tuning. The monitoring uses a standard PT100 blackboard temperature sensor.

2)The temperature of the sink is controlled by a color touch screen program and a Korean temperature controller. The sink is located at the bottom of the box and is equipped with an electric water heater. During the testing process, there is a dark condensation process that requires the box to generate saturated water vapor at a relatively high temperature. When the water vapor encounters a relatively cold surface of the sample, it will condense on the surface of the sample.