1、 Overview of ZW unobstructed self-priming sewage pump:

ZW type stainless steel self-priming pump, also known as solid-liquid pump or impurity pump. This series of pumps has a unique hydraulic design that combines self-priming and non clogging sewage discharge. It can be used like a typical water self-priming pump, without the need for a bottom valve or water injection, and can also suck up pollutants containing large solid particles, fibers, sediment, impurities, fecal treatment, and all engineering wastewater,

The impeller is enclosed in a separate impeller chamber, which is connected to a pressurized water chamber. When the impeller rotates, the liquid in the pump generates a strong axial vortex, creating a vacuum at the inlet and a head at the outlet. Therefore, impurities can be discharged from the pressure chamber, so its flow channel is completely unobstructed, and its sewage discharge effect is unparalleled by other self-priming sewage pumps.

2、 Purpose of ZW self-priming sewage pump:

It can be widely applied to industries such as municipal sewage engineering, light industry, papermaking, textile, food, chemical industry, electric power, petroleum, mining, and river pond aquaculture. It is currently the ideal impurity pump for pumping solid particles, fibers, slurries, and mixed suspensions in China.

3、 Applicable conditions for ZW stainless steel self-priming pump:

Environmental temperature ≤ 45 ℃, medium temperature ≤ 60 ℃.

The pH value of the medium is 6-9 for cast iron pumps and 3-14 for stainless steel pumps.

The maximum diameter of the particles is 60% of the pump diameter, and the fiber length is 5 times the diameter.

The total weight of impurities in the medium shall not exceed 15% of the total amount of the medium, and the specific gravity of the medium shall not exceed 1240 kg/cubic meter.

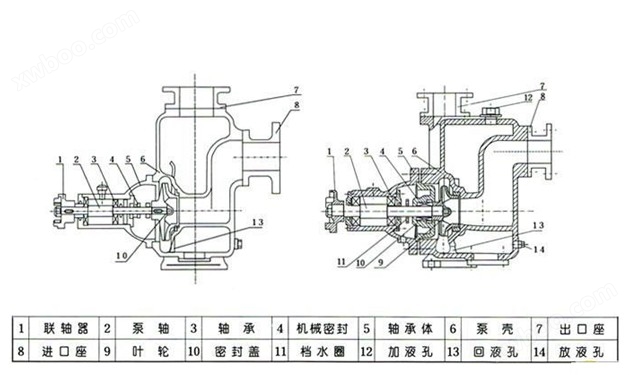

4、 Structural diagram of ZW stainless steel self-priming sewage pump

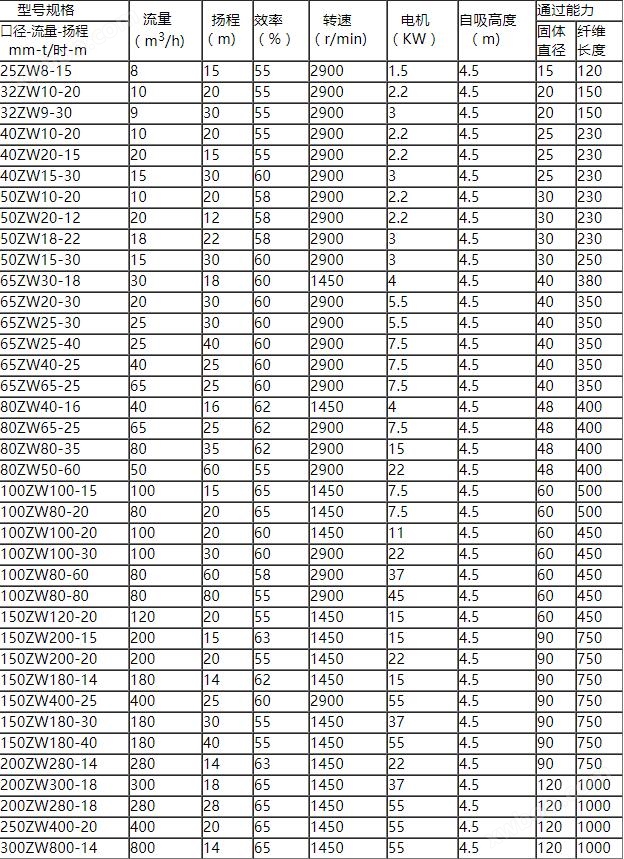

5、 Performance parameter table of ZW stainless steel self-priming pump

(1) Preparation and inspection work before starting;

1. This series of self-priming pumps is lubricated with high-quality calcium based grease and No. 10 engine oil according to the working and operating conditions of the pump. If a grease lubricated pump is used, grease should be regularly added to the bearing box. If a machine oil lubricated pump is used, the oil level should be sufficient.

2. Check if the liquid storage inside the pump casing is higher than the upper edge of the impeller. If it is insufficient, the liquid can be directly injected into the pump body from the filling port on the pump casing. The pump should not be started when the liquid storage is insufficient, otherwise the pump cannot work normally and the mechanical seal may be damaged.

3. Check if there is any jamming or collision of the rotating parts of the pump.

4. Check for loose nuts at the pump body feet and connections.

5. Check the coaxiality and parallelism between the pump shaft and the motor shaft.

6. Check if there is any air leakage in the inlet pipeline, and if there is any, try to eliminate it.

7. Open the valve of the suction pipeline and slightly open (not fully open) the outlet control valve.

(2) Starting and operation:

1. Tap the self-priming pump and pay attention to whether the direction of the pump shaft is correct.

2. Pay attention to any abnormal sounds or vibrations during rotation.

3. Pay attention to the readings of the pressure gauge and vacuum gauge. After starting, when the readings of the pressure gauge and vacuum gauge fluctuate for a period of time and stabilize, it indicates that the pump has been filled with liquid and normal infusion operation has begun.

4. Before the pump enters normal infusion operation, during the self suction process, special attention should be paid to the increase in water temperature inside the pump. If this process is too long and the water temperature inside the pump is too high, the pump should be stopped to check the cause.

5. If the temperature of the liquid inside the pump is too high and causes difficulty in self-priming, it can be temporarily stopped. The liquid in the discharge pipeline can be used to flow back into the pump or to directly replenish the liquid into the pump through the storage port on the pump body, so as to cool down the liquid inside the pump, and then start it.

6. If the pump experiences strong vibration and noise during operation, it may be caused by cavitation of the pump, which is the cause of cavitation

There are two types: one is that the inlet pipe flow rate is too high, and the other is that the suction stroke is too high. When the flow rate is too high, the outlet control valve can be adjusted to increase the pressure gauge reading. If there is a blockage in the inlet pipeline, it should be promptly eliminated; If the suction is too high, the installation height of the pump can be appropriately reduced.

7. The pump stops for some reason during operation and needs to be restarted. The inlet and outlet control valves should be slightly opened (not fully closed) to facilitate the discharge of gas from the outlet during the self-priming process and ensure that the pump starts under lighter loads.

8. Pay attention to checking for leaks in the piping system.

(3) Stop the pump:

1. Firstly, the gate valve on the discharge pipeline must be closed.

2. Stop the pump from rotating.

3. In cold seasons, the liquid stored in the pump body and the water in the cooling chamber of the bearing body should be emptied to prevent freezing and cracking of the components.