On the basis of introducing German torque sensor technology, a professional sensor for measuring torque parameters has been developed for the disc torque sensor. It has a compact appearance and multiple selectable installation methods. Not only suitable for laboratories, but also for industrial environments. Both power supply and measurement signals are transmitted through non-contact methods, which are suitable for long-term use with low wear and tear, and do not require any maintenance. For different applications, speed testing can also be added to the sensor.

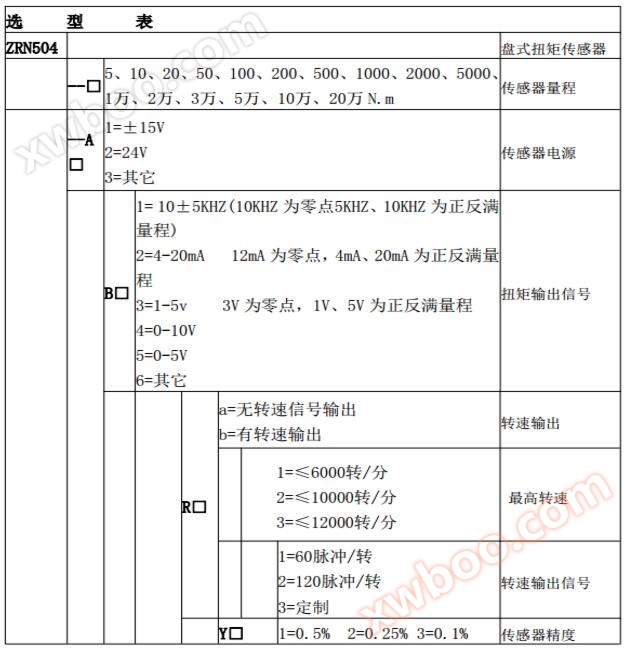

Example of selection:

The corresponding parameters for ZRN504-100A2B2Rb11Y1 are: disc torque sensor - range 0-100N. m Power supply: 24V output 4-20mA

Speed ≤ 6000 revolutions per minute, output 60 pulses per revolution, sensor accuracy of 0.5%

Note: Due to its compact structure, the ZRN504 disc torque sensor requires an external speed measurement sensor.

1、 Characteristics:

This series of torque sensors is a signal sensor developed specifically for transmitting torque parameters based on standard torque strain sensors.

The ZRN504 torque sensor is the shortest axial length form of the ZRN503 torque sensor The diameter of the flat key and shaft hole in this form must be customized according to user requirements

This series of torque signal sensors has:

1. There are no bearings between the stationary shell and the rotating disk, which can adapt to long-term, high-speed operation.

2. High precision and good stability; 5. Small size, light weight, easy to install;

3. Continuous transmission of forward and reverse torque signals without repeated zeroing;

4. Without wear parts such as collector rings, it can operate at high speed for a long time;

5. Strong anti-interference ability;

2、 Technical indicators

1. Range: 5, 10, 20, 50, 100N · m; 2. Accuracy: 0.5% F · S;

3. Suitable for speeds below 6000 revolutions per minute

4. Environmental temperature: 0 ℃ -50 ℃ 5. Frequency response: 100 μ s 6. Self weight=2.8Kg

7. Output signal: 0-12v square wave frequency; Load current<10mA

Zero torque: 10 KHZ; Positive full range: 15KHZ; Reverse full range: 5 KHZ;

8. Signal socket: (1) 0V. (2)+15V. (3) -15V. (4) empty (5) Torque signal

III install

The ZRN504 torque sensor consists of a stationary housing and a rotating disk

2. Place the stationary shell on the outside of the rotating disk according to the positioning color points The positioning color point cannot be reversed!

3. Connect one end of the rotating disc to the power or load through a flange coupling

4. Fix the stationary shell on the base, adjust the gap, and ensure that there is no contact between the stationary shell and the rotating disk!

4、 Signal processing

1. Use ZRN series torque meter to directly display torque values;

2. Directly send the torque frequency signal to the computer or PLD for processing;

3. Convert to 4-20mA or 1-5V analog signal