XBD-HL Constant Pressure Tangent Pump

1、 XBD-HL Constant Pressure Buffer Multi stage Fire Pump Product Features:

1. No matter how the flow rate or inlet pressure changes, the head remains constant, truly meeting national fire safety standards.

2. The head can be freely adjusted within the specified range.

3. Made of stainless steel material, ensuring that the water pump does not rust and can start safely and reliably in an instant.

4. It has a slow closing and check function.

2、 Main purpose:

1. Fire water supply

2. Domestic water supply

3. Cooling system

4. Hydraulic flushing

5. Environmental protection water supply and drainage

6. Boiler feedwater

3、 User feedback:

4、 Installation technical requirements:

All water pumps are equipped with a base. When the pump room is set on the bottom floor, it can be directly installed on the concrete foundation with anchor bolts.

If installed on a floor or in situations where high isolation pads are required, a combination of spring dampers and rubber deceleration pads can be used for better vibration reduction effect.

Rubber flexible joints must be installed at the inlet and outlet pipe ends of the water pump, and the weight of the pipeline system must not be added to the water pump. The inlet and outlet pipes should be fixed with elastic hangers.

1. The pump unit is horizontally placed, and a metal pad is used to level the anchor bolt hole under the base. The nut is tightened, and cement is poured to fix the base firmly. The installation prevents unstable three-point contact of the base.

2. Connect the motor power supply, and the motor should rotate in the direction indicated by the arrow on the bracket (when viewed from the motor end, the rotation direction is clockwise)

3. The inlet and outlet of the pump should be connected to tap water, and the diameter of the pipe should be the same as the inlet diameter of the pump. The inlet and outlet pipelines should have good neutrality and appropriate length, and the pump should not be subjected to significant external forces.

4. Before starting, the following preparations should be made:

Rotate the motor shaft by hand, and the rotation should be flexible without any jamming phenomenon.

Before starting pump B, the pump should be filled with medium.

The allowable leakage rate of the C seal is 5ml/h. If it is considered that the leakage rate of the seal is too large, replace the mechanical seal.

5、 Troubleshooting:

|

Fault phenomenon

|

Possible reasons |

exclusion method |

|

The pump cannot be started |

1Not meeting the starting conditions (such as power on, etc.) 2The impeller is stuck 3Motor malfunction 4The pump has frozen

|

1 Check if it meets the starting conditions 2 Maintenance and replacement 3 Check and repair 4 Be careful with the heating pump |

|

The pump is not producing water |

1cavitation 2The suction and discharge valves are closed due to air leakage in the suction pipe section 3Blockage of suction pipe 4The rotation direction is reversed

|

1Ensure import pressure 2Replace and open the suction and discharge valves 3Disassemble and remove foreign objects 4Correctly connect the motor wiring |

|

Unable to achieve the designed traffic |

1There is air inhalation 2There are foreign objects blocking the impeller 3The gap between the impeller and the shell increases 4The flow resistance of the outlet pipe is too high

|

1Check the suction pipe section and replace it 2Disassemble and remove foreign objects 3Replace or readjust 4Increase the diameter of the pipe to reduce local resistance

|

|

Pump leakage |

1Mechanical seal damage 2、ODamaged O-ring

|

1Replace with new parts

|

|

Pump vibration |

1Pump cavitation 2The pump is not securely fastened 3Damaged pump shaft or bearing 4Localized blockage or damage to the impeller 5Excessive traffic

|

1Check for air leakage and pressure at the inlet 2Is it guaranteed to fix the pump tightly 3Replace 4Disassemble, inspect or replace 5Adjust (close) the outlet valve

|

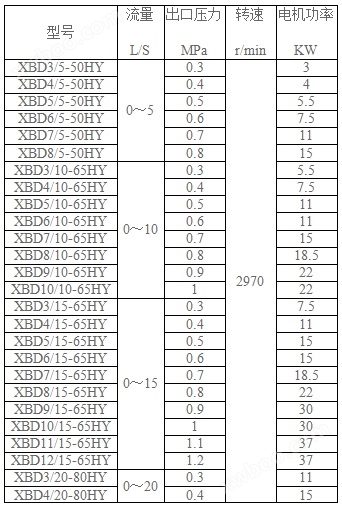

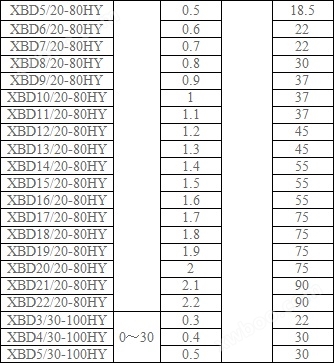

6、 Parameter model: