Long service life

Precision machining and balancing of rotors, high-strength surface treatment, wear-resistant rotation, non-contact sealing, self-cleaning function, and good lubrication of bearings ensure the long-term normal operation of flow meters through exquisite design and craftsmanship.

Wide range

The range of different specifications of flow meters is 40:1 to 260:1.

High precision, high reliability

Permanent high-precision without adjustment, unaffected by changes in medium conditions.

Starting traffic is extremely low

The starting flow rate of different specifications of flow meters is 0.03m3/h to 1.20m3/h.

Low pressure loss

The pressure loss of different specifications of flow meters ranges from 0.08kPa to 0.70kPa.

Good universality

All specifications of flowmeter body components can use universal accessories.

Good interchangeability

Attachments can be interchanged with table body components of the same specifications.

Multiple structural forms

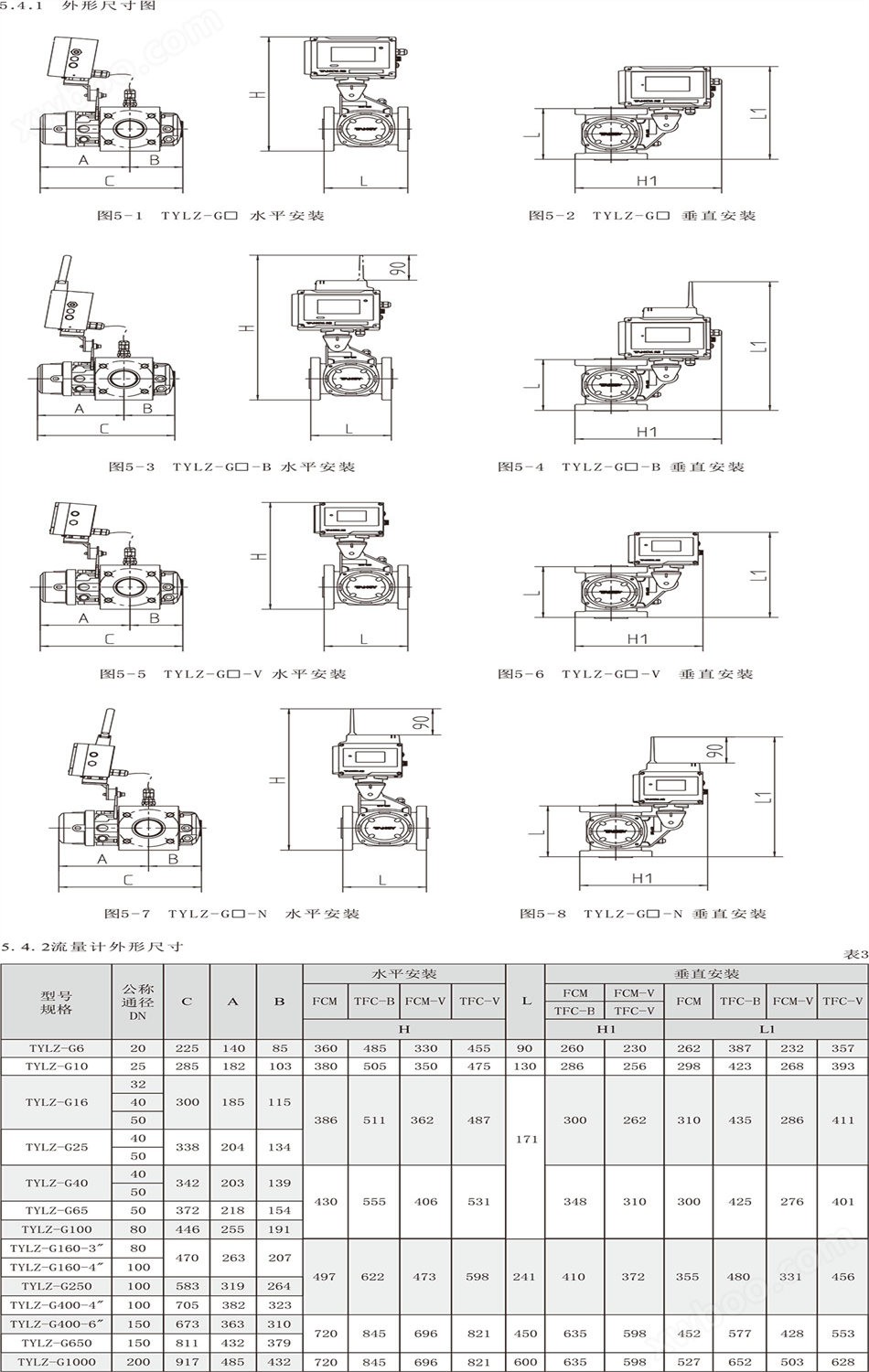

a. TYLZ-G □ type: equipped with FCM type volume correction instrument, with automatic temperature and pressure correction;

b. TYLZ-G □ - V type: equipped with FCM-V simple volume correction instrument, temperature and pressure can be adjusted or detected according to needs.

c. TYLZ-G □ - B type: equipped with TFC-B volume correction instrument, intrinsically safe explosion-proof type, with automatic temperature and pressure correction, and can be powered by an internal battery as needed. Realize wireless communication (GPRS CDMA NB IoT) with a daily frequency of no more than 10 times, or real-time online wireless communication powered by an external power source and 5V DC;

d. TYLZ-G □ - N type: equipped with TFC-V simple volume correction instrument, temperature and pressure can be adjusted or detected according to needs. This product is powered by an internal battery and generally achieves wireless communication once a day.

When ordering this product, users should choose the appropriate specifications and correction instrument configuration based on the nominal diameter of the pipeline, flow range, maximum pressure of the medium, and usage requirements. And fill in the following format in detail and correctly.

There are two methods for installing flow meters, namely horizontal installation and vertical installation (vertical installation is recommended). When the flowmeter is installed vertically, the inlet end of the medium should be above, and the airflow should flow from top to bottom. This installation enables the rotor to have self-cleaning ability against dirt; When installed horizontally, the axis of the inlet and outlet ends of the flowmeter must not be lower than the axis of the pipeline to prevent dirt and impurities in the medium from accumulating in the measuring chamber of the flowmeter and affecting normal speed. During installation, a filter or mesh (120-200 mesh) must be installed upstream of the flowmeter to improve the purity of the medium. (The filter is provided by our company)

Typical installation methods are shown in Figures 7 and 8

5.4.6 Precautions for flowmeter installation

5.4.6.1 It is strictly prohibited to weld pipeline flanges online with flow meters.

Before installing the flowmeter, impurities in the pipeline must be removed (special attention should be paid to removing impurities in the elbow in front of the flowmeter when installed vertically) to avoid foreign objects entering and damaging the flowmeter. The inner wall of the pipeline should be clean and free of scale.

Before installing the flowmeter in the pipeline, check whether the waist wheel rotates flexibly.

5.4.6.4 During installation, the sealing element shall not protrude into the pipeline, and there shall be no visual deviation between the inlet and outlet axis of the flowmeter and the axis of the connected pipeline.

When installing the flowmeter horizontally, it is recommended to install a steel expansion joint (compensator) behind the flowmeter. The expansion joint must meet the requirements of the nominal diameter and nominal pressure of the pipeline design. (Expansion joint is used as a compensation for pipeline stress and to facilitate the installation and disassembly of flow meters)

After installation, unscrew the screw plug above the synchronous gear and insert an equivalent hexagonal wrench into the synchronous gear. Rotate the rotor and check if the waist wheel rotates freely. If there is any restriction during rotation, the instrument should be removed, the dirt should be cleared, and then reinstalled. After the waist wheel rotates freely, tighten the screw plug.

5.4.6.7 Red and yellow warning signs should be retained on the flow meter.

5.4.6.8 When installing the flowmeter for outdoor use, it is recommended to add a protective cover to prevent rainwater from entering and direct sunlight from affecting the service life of the flowmeter.

5.4.6.9 There should be no strong external magnetic field interference or strong mechanical vibration around the flowmeter.

5.4.6.10 The flowmeter must be reliably grounded, but must not be shared with the grounding wire of the high-voltage system.

5.4.6.11 There should be no gas present at the installation site that has a corrosive effect on the aluminum alloy.

5.4.6.12 When external power supply or wiring is required, it must be carried out according to the requirements in the corresponding correction instrument manual, otherwise it may damage the instrument or cause safety issues.

5.4.6.13 When installing the flow meters of TFC-B and TFC-V correction instruments in a metal box (such as a pressure regulating box), a dedicated extension antenna should be selected and inserted outside the metal box.