VIP member

Spray adsorption tower, acid mist absorption tower

Spray adsorption tower acid mist absorption tower spray absorption industrial waste gas treatment equipment has special effects on the absorption, ads

Product details

1Spray adsorption tower Acid mist absorption towerworking principle:

Spray adsorption tower Acid mist absorption towerAdopting differential contact counter current method. Acidic gas enters the purification tower from the inlet below the tower in a tangential direction. Under the power of the ventilation fan, it quickly fills the space in the inlet section and then uniformly rises through the equalization section to the absorption section of the filling material. On the surface of the filler, acidic substances in the gas phase react chemically with alkaline substances in the liquid phase, producing substances (mostly soluble acids) that flow into the lower storage tank along with the absorbent. The unabsorbed acidic gas continues to rise and enter the stage spraying section. In the spray section, the absorbing liquid is sprayed at high speed from uniformly distributed nozzles, forming countless small droplets that are fully mixed and in contact with the gas, continuing to undergo chemical reactions. Then, the acidic gas rises to the secondary packing section and spray section for a similar absorption process as the _ stage. _The density of the nozzle at level and level is different, the spray pressure is different, and the range of absorbed acidic gas concentration is also different. The process of contact between the spray section and the packing section is also a process of heat and mass transfer. By controlling the flow rate and retention time of the empty tower, the process can be fully and stably carried out. The upper part of the tower body is the defogging section, where the absorbing liquid droplets trapped in the gas are removed. The treated clean air is discharged into the atmosphere through the exhaust pipe at the upper end of the purification tower.

The main harmful gases treated by PP washing tower are acid mist (H2S04), hydrogen chloride (HCL) gas, hydrogen fluoride (HF) gas, chromium mist (CrO3), hydrogen cyanide (HCN) gas, hydrogen sulfide (H2S), ammonia (NH3), alkali vapor and other water-soluble gases. Using sodium hydroxide as the absorption and neutralization solution, with a concentration of 2-6%, the purification efficiency is above 95%.

Treatment of waste gas types: adsorption purification of waste gas from organic solvents such as benzene, alcohols, ketones, esters, and gasoline.

2、 Spray adsorption tower, acid mist absorption tower, application scope:

Spray adsorption tower acid mist absorption tower spray absorption industrial waste gas treatment equipment has special effects on the absorption, adsorption, oxidation, and neutralization of acid mist, alkali mist, and paint mist; Meet the industrial waste gas emission standards. Suitable for industries and fields such as electroplating production, surface treatment, monocrystalline silicon acid washing, semiconductor cleaning, electronic manufacturing, coating production, etc.

3、 Spray adsorption tower acid mist absorption tower structure:

Qingyuan Environmental Protection PP Spray Adsorption Tower Acid Mist Absorption Tower is divided into single tower body and double tower body. It adopts a circular tower body and is connected in sections with flanges. The PP washing tower is composed of a storage tank, tower body, inlet section, spray layer, packing layer, cyclone defogging layer, outlet cone cap, observation hole, etc.The exhaust gas scrubbing tower itself includes a body, a filling layer, a defogging layer, a circulating sprinkler pipeline, and a circulating water tank.

The PP spray adsorption tower acid mist absorption tower body includes a waste gas inlet, outlet, window, maintenance inlet hole, and internal structure for supporting and fixing the washing tower to ensure the corrosion resistance of the waste gas washing tower and increase its service life.

Features: PP washing tower has low noise, smooth operation, simple operation, and convenience; _Used for neutralization treatment of acidic and alkaline gases generated in the electroplating industry and surface treatment of Wu Duo, using a PP board with randomly adjustable air volume.

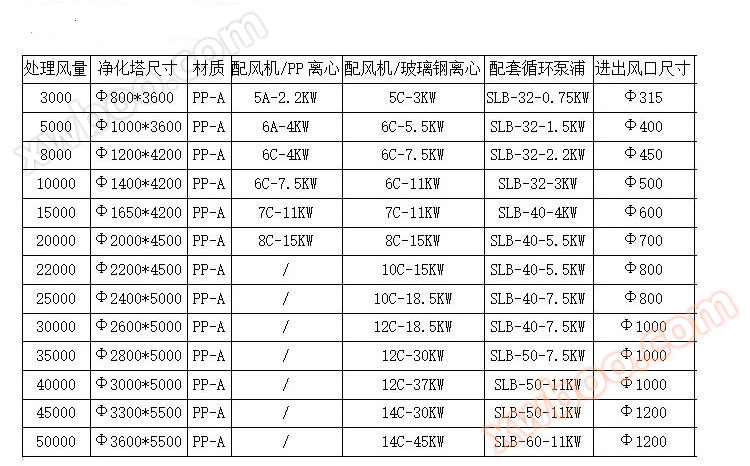

4、 Spray adsorption tower acid mist absorption tower technical parameters:

5、 Detailed description of spray adsorption tower acid mist absorption tower:

(1) Composite fiberglass storage tank and filling pipe, with a filtrate device added to the suction pipe, and the inlet section made of composite fiberglass.

(2) The secondary spray section adopts a row of Y-1 nylon nozzles, Paul ring filter material, and organic glass inspection holes.

(3) The effective water blocking section is equipped with a swirl plate to enhance the water blocking effect.

(4) Fiberglass hood cover.

(5) F4-72 fiberglass centrifugal fan.

(6) Plastic water pump or stainless steel centrifugal pump.

(7) Other accessories such as plastic pipe fittings, valves, fixed brackets, maintenance ladders, and air inlet ducts can be customized by users when ordering.

Online inquiry