Characteristics of SMH series multi cylinder hydraulic cone crusher equipment

-

Reasonable structure

The crushing principle and technical parameters are excellent, the operation is reliable, and the operating cost is low.

-

Has high crushing power

High production efficiency, high output, and good product grain shape.

-

Hydraulic system is convenient and reliable

Can provide safe and effective overload protection.

-

Multiple crushing chambers

Adapt to the granularity requirements of a wide range of products.

-

Adopting hydraulic adjustment and hydraulic cleaning chamber setting

The degree of automation has been greatly improved.

Technical advantages of SMH series multi cylinder hydraulic cone crusher

-

Optimized cavity design, higher output

Under the same diameter of the crushing wall, the crushing stroke is longer and the crushing ratio is larger. Under full chamber conditions, the laminated crushing effect can be more effectively utilized, resulting in a more stable particle size composition and better particle shape (cube) of the final product.

-

Shorter parking time

The SMH series multi cylinder hydraulic cone crusher adopts hydraulic locking and overload protection methods. When an unbreakable foreign object enters the crushing chamber, the hydraulic system can smoothly release the impact force to protect the main engine, and return to the original discharge port after the foreign object passes through, avoiding the phenomenon of vehicle blockage.

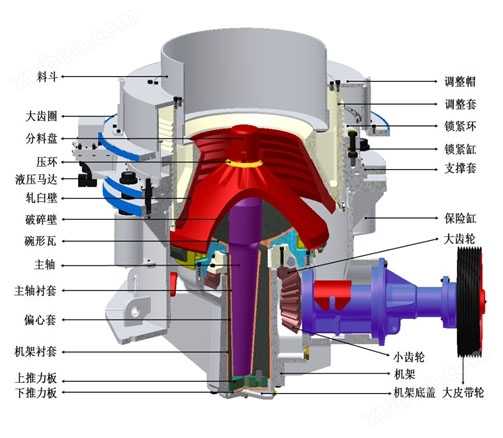

Working principle of SMH series multi cylinder hydraulic cone crusher

This crusher mainly consists of a frame, transmission shaft, eccentric sleeve, bowl shaped bearing frame, crushing cone, adjusting device, adjusting sleeve, lubrication system, and hydraulic system.

When the crusher is working, the electric motor drives the eccentric sleeve to rotate through the transmission shaft and a pair of bevel gears. The axis of the crushing cone rotates under the pressure of the eccentric sleeve, causing the surface of the crushing wall to sometimes approach and sometimes leave the surface of the rolling mill bowl, thereby continuously squeezing and crushing the ore in the crushing chamber.

The material enters the crusher through the upper feeding port, and after crushing, it is discharged through the lower discharge port of the crusher.

By using the principle of intergranular lamination to design a special crushing chamber and matching the rotational speed, the crushing ratio and yield have been significantly improved, greatly increasing the content of finished material cubes.

Adopting hydraulic protection and hydraulic cleaning, with a high degree of automation. This machine can be hydraulically lifted and automatically discharged in the event of iron and momentary blockage, eliminating the hassle of manual discharge for the original spring cone crusher, making maintenance easier and more cost-effective.

Adopting hydraulic adjustment and thin oil lubrication, the performance is stable and reliable. And effective labyrinth sealing method is adopted to avoid the defect of easy mixing of water and oil in the original spring cone crusher.

Product Display

Structure diagram of SMH series multi cylinder hydraulic cone crusher

Technical parameters of SMH series standard multi cylinder hydraulic cone crusher

| model | Maximum feeding size (mm) | Range of ore discharge outlet (mm) | Motor power (kw) | Production capacity (ton/hour) - open loop, closed edge discharge port (mm) | Weight (t) | |||||||||||

| 9 | 13 | 16 | 19 | 22 | 26 | 32 | 38 | 51 | 63 | 76 | 89 | |||||

| SMH120C | 160 | 22~32 | 75-90 | 120 | 130 | 150 | 12.5 | |||||||||

| SMH120M | 130 | 13~26 | 70 | 85 | 100 | 120 | 130 | 12.5 | ||||||||

| SMH120F | 50 | 9~19 | 58 | 70 | 85 | 95 | 110 | 12.5 | ||||||||

| SMH180C | 180 | 22~32 | 132-160 | 185 | 195 | 215 | 13.5 | |||||||||

| SMH180M | 140 | 13~32 | 90 | 115 | 135 | 160 | 180 | 200 | 13.5 | |||||||

| SMH180F | 60 | 9~22 | 60 | 80 | 100 | 120 | 140 | 13.5 | ||||||||

| SMH250EC | 260 | 26~51 | 160-220 | 250 | 290 | 340 | 395 | 24.2 | ||||||||

| SMH250C | 220 | 19~51 | 182 | 209 | 236 | 279 | 334 | 365 | 24.2 | |||||||

| SMH250M | 150 | 16~38 | 140 | 165 | 185 | 220 | 275 | 330 | 24.2 | |||||||

| SMH250F | 115 | 13~31 | 115 | 133 | 156 | 176 | 192 | 226 | 24.2 | |||||||

| SMH350EC | 315 | 38~64 | 250-280 | 555 | 649 | 766 | 45.85 | |||||||||

| SMH350C | 230 | 26~64 | 366 | 430 | 468 | 629 | 657 | 45.85 | ||||||||

| SMH350M | 205 | 22~52 | 296 | 343 | 387 | 427 | 479 | 45.85 | ||||||||

| SMH350F | 180 | 16~38 | 212 | 239 | 270 | 320 | 355 | 374 | 45.85 | |||||||

| SMH550EC | 450 | 38~89 | 355-400 | 920 | 1179 | 1380 | 1475 | 1566 | 86.7 | |||||||

| SMH550C | 350 | 31~76 | 800 | 850 | 1100 | 1288 | 1398 | 86.7 | ||||||||

| SMH550M | 320 | 25~63 | 612 | 735 | 815 | 980 | 1137 | 86.7 | ||||||||

| SMH550F | 268 | 19~52 | 392 | 453 | 535 | 620 | 725 | 867 | 86.7 | |||||||

Technical parameters of SMH series short head multi cylinder hydraulic cone crusher

| model | Maximum feeding size (mm) | Range of ore discharge outlet (mm) | Motor power (kw) | Production capacity (ton/hour) - open loop, closed edge discharge port (mm) | Weight (t) | ||||||||||

| 3 | 5 | 6 | 9 | 13 | 16 | 19 | 22 | 26 | 32 | 38 | |||||

| SMH120DC | 70 | 6-9 | 75-90 | 62 | 82 | 102 | 123 | 138 | 12.5 | ||||||

| SMH120DM | 51 | 5-16 | 45 | 58 | 78 | 99 | 116 | 12.5 | |||||||

| SMH120DF | 35 | 3-13 | 30 | 45 | 58 | 78 | 95 | 12.5 | |||||||

| SMH180DC | 70 | 6-9 | 75-90 | 72 | 90 | 108 | 131 | 158 | 13.5 | ||||||

| SMH180DM | 51 | 5-16 | 68 | 76 | 95 | 118 | 145 | 13.5 | |||||||

| SMH180DF | 35 | 3-13 | 70 | 82 | 95 | 120 | 13.5 | ||||||||

| SMH250DC | 89 | 9-22 | 160-220 | 126 | 168 | 196 | 215 | 252 | 24.2 | ||||||

| SMH250DM | 70 | 6-16 | 88 | 117 | 156 | 172 | 24.2 | ||||||||

| SMH250DF | 54 | 5-16 | 63 | 86 | 115 | 143 | 169 | 24.2 | |||||||

| SMH350DEC | 133 | 13-25 | 250-280 | 262 | 308 | 322 | 358 | 385 | 45.85 | ||||||

| SMH350DC | 133 | 10-25 | 208 | 262 | 308 | 322 | 358 | 385 | 45.85 | ||||||

| SMH350DM | 89 | 6-19 | 136 | 186 | 233 | 260 | 293 | 45.85 | |||||||

| SMH350DF | 70 | 6-13 | 130 | 168 | 215 | 45.85 | |||||||||

| SMH550DEC | 203 | 16-25 | 355-400 | 516 | 593 | 665 | 696 | 86.7 | |||||||

| SMH550DC | 178 | 13-25 | 455 | 498 | 552 | 608 | 643 | 86.7 | |||||||

| SMH550DM | 133 | 10-19 | 355 | 416 | 472 | 530 | 86.7 | ||||||||

| SMH550DF | 105 | 6-16 | 276 | 355 | 385 | 448 | 86.7 | ||||||||

Note:

1. The processing capacity is capable of crushing materials with a density of 1.6x103kg/m3Time's data. The production capacity is related to the physical properties of the crushed materials, feeding methods, feeding particle size and composition, and other working conditions.

2. Our products are constantly being updated and improved, and Shanmei reserves the right to change parameters and designs without prior notice to users. If the sample data is inconsistent with the website data, this website shall prevail.

3. The above product configurations may not be factory standard configurations. Please consult us in detail when purchasing.