SGR series hot water pipeline pump product overview

The SGR series vertical hot water pipeline pump (hereinafter referred to as the electric pump) produced by our company follows the standard JB/T6878-2006 for pipeline pumps. This series of products is a novel electric pump developed for pipeline pressure boosting transportation and solving the problem of low pipeline pressure. Due to the use of advanced mechanical seals and the direct installation of impellers on the motor spindle, it has the characteristics of high efficiency, low power consumption, compact structure, small size, light weight, and convenient decoration. And it can be used in series according to the needs of head and flow rate. This electric pump consists of three parts: an electric motor, a mechanical seal, and a water pump. The motor is a single-phase or three-phase asynchronous motor; The mechanical seal is used between the water pump and the electric motor. The rotor shaft of the electric pump is made of high-quality carbon steel material and has undergone anti-corrosion treatment to ensure that the shaft has more reliable mechanical strength, which can effectively improve the wear resistance and corrosion resistance of the shaft. At the same time, it is also convenient for the maintenance and disassembly of the impeller. 'O' - shaped rubber sealing rings are used for static sealing at each fixed stop seal of the pump.

Application of SGR series hot water pipeline pump

1. This series of electric pumps is suitable for boosting water supply in high-rise buildings, garden irrigation, pipeline boosting, cold and hot water circulation, transportation of flammable and explosive liquids and corrosive liquids, as well as various boiler water supply, HVAC chemical, petroleum pipeline equipment circulation, and boosting matching.

2. SG ordinary type is suitable for high-rise building pressurized water supply, garden sprinkler irrigation, cooling tower water supply, long-distance water supply, refrigeration flushing, bathroom and other cold and warm water circulation; Use temperature below 80 ℃.

3. SGR hot water type is suitable for high-temperature hot water pressurized circulation in industries such as greenhouses and boilers; Use temperature below 100 ℃.

Scope of application of SGR series hot water pipeline pump

1. Suitable for urban environmental protection, construction, fire protection, chemical, pharmaceutical, dye printing and dyeing, brewing, electricity, electroplating, papermaking, petroleum, mining, equipment cooling, etc.

2. Suitable for transporting clean water and other liquids with physical and chemical properties similar to clean water.

3. With the rocker nozzle, the water can be washed into the air and dispersed into small raindrops for spray. It is a good machine for farms, nurseries, orchards and tea gardens.

4. It can be used in conjunction with any type and specification of filter press, and is an ideal pump for feeding slurry to the filter press for pressure filtration.

SGR series hot water pipeline pump usage conditions

1. The water pressure of the imported pipe shall not exceed 0.3MPa and not be less than 0.02MPa;

2. The water quality should be clean water without fibers or solid particles, and soft water should be used for hot water;

3. Medium temperature: Cold water shall not be lower than 0 ℃;

4. The ambient temperature should not exceed+45 ℃;

5. The power frequency is 50Hz/60Hz, the voltage is single-phase 220V/240V, three-phase 380V/415V/460V/660V, and the voltage fluctuation range is ± 10% of the rated value.

SGR series hot water pipeline pump model description

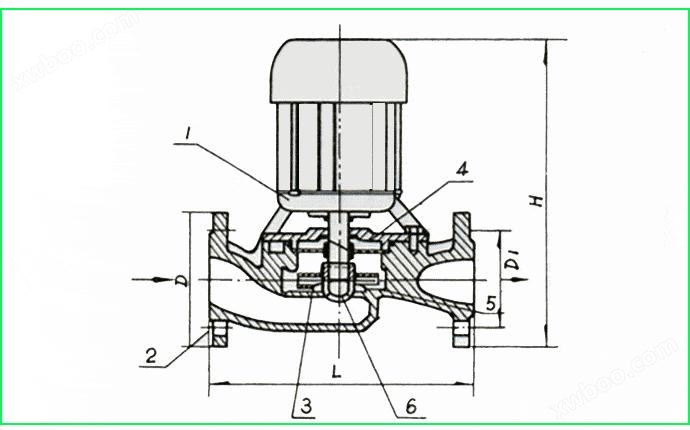

Structure diagram of SGR series hot water pipeline pump

SGR series hot water pipeline pump model and performance parameters

| model |

caliber (mm) |

internet traffic (m3/h) |

lift (m) |

efficiency (%) |

electrical machinery power (kw) |

voltage (v) |

synchronous rotational speed (r/min) |

The installation size of the connecting flange shall be manufactured according to the GB4216-84 standard |

weight (kg) |

|||||||

| L | H | D | D1 | D2 | b | d | (nn) | |||||||||

| SGR25-4-20 | 25 | 4 | 20 | 60 | 0.75 | 220 | 3000 | 270 | 370 | 100 | 75 | 60 | 14 | 12 | 4 | 29 |

| SGR25-3-30 | 25 | 3 | 30 | 60 | 0.75 | 220 | 3000 | 290 | 370 | 100 | 75 | 60 | 14 | 12 | 4 | 30 |

| SGR32-5-20 | 32 | 5 | 20 | 60 | 0.75 | 220 | 3000 | 270 | 380 | 120 | 90 | 70 | 16 | 14 | 4 | 30 |

| SGR40-6-20 | 40 | 6 | 20 | 60 | 0.75 | 220 | 3000 | 270 | 390 | 130 | 100 | 80 | 16 | 14 | 4 | 32 |

| SGR50-10-7.5 | 50 | 10 | 7.5 | 55 | 0.75 | 220 | 3000 | 255 | 390 | 140 | 110 | 90 | 16 | 14 | 4 | 32 |

| SGR50-10-15 | 50 | 10 | 15 | 60 | 0.75 | 220 | 3000 | 270 | 400 | 140 | 110 | 90 | 16 | 14 | 4 |

33 |

| SGR25-4-20 | 25 | 4 | 20 | 60 | 0.75 | 380 | 3000 | 270 | 370 | 100 | 75 | 60 | 14 | 12 | 4 | 29 |

| SGR25-3-30 | 25 | 3 | 30 | 60 | 0.75 | 380 | 3000 | 290 | 370 | 100 | 75 | 60 | 14 | 12 | 4 | 28 |

| SGR25-6.5-30 | 25 | 6.5 | 30 | 60 | 1.5 | 380 | 3000 | 290 | 420 | 100 | 75 | 60 | 14 | 12 | 4 | 37 |

| SGR25-10-50 | 25 | 10 | 50 | 60 | 4 | 380 | 3000 | 350 | 500 | 115 | 85 | 65 | 16 | 14 | 4 | 58 |

| SGR32-5-20 | 32 | 5 | 20 | 60 | 0.75 | 380 | 3000 | 270 | 380 | 120 | 90 | 70 | 16 | 14 | 4 | 28 |

| SGR32-8-30 | 32 | 8 | 30 | 65 | 1.5 | 380 | 3000 | 290 | 420 | 120 | 90 | 70 | 16 | 14 | 4 | 38 |

| SGR32-15-40 | 32 | 15 | 40 | 60 | 4 | 380 | 3000 | 350 | 510 | 135 | 100 | 78 | 18 | 18 | 4 | 60 |

| SGR32-12-50 | 32 | 12 | 50 | 60 | 4 | 380 | 3000 | 350 | 510 | 135 | 100 | 78 | 18 | 18 | 4 | 61 |

| SGR32-14-80 | 32 | 14 | 80 | 60 | 7.5 | 380 | 3000 | 420 | 540 | 130 | 100 | 78 | 18 | 18 | 4 | 98 |

| SGR40-6-20 | 40 | 6 | 20 | 60 | 0.75 | 380 | 3000 | 270 | 390 | 130 | 100 | 80 | 16 | 14 | 4 | 30 |

| SGR40-9-30 | 40 | 9 | 30 | 60 | 1.5 | 380 | 3000 | 290 | 430 | 145 | 110 | 80 | 16 | 14 | 4 | 40 |

| SGR40-18-40 | 40 | 18 | 40 | 60 | 4 | 380 | 3000 | 350 | 520 | 145 | 110 | 85 | 18 | 18 | 4 | 61 |

| SGR40-15-50 | 40 | 15 | 50 | 60 | 4 | 380 | 3000 | 350 | 520 | 145 | 110 | 85 | 18 | 18 | 4 | 62 |

| SGR40-18-65 | 40 | 18 | 65 | 65 | 7.5 | 380 | 3000 | 420 | 550 | 145 | 110 | 85 | 18 | 18 | 4 | 98 |

| SGR40-15-80 | 40 | 15 | 80 | 65 | 7.5 | 380 | 3000 | 420 | 550 | 145 | 110 | 85 | 18 | 18 | 4 | 100 |

| SGR40-15-30 | 40 | 15 | 30 | 65 | 2.2 | 380 | 3000 | 420 | 550 | 145 | 110 | 85 | 18 | 18 | 4 | 100 |

| SGR50-10-7.5 | 50 | 10 | 7.5 | 55 | 0.75 | 380 | 3000 | 225 | 390 | 140 | 110 | 90 | 16 | 14 | 4 | 30 |

| SGR50-10-15 | 50 | 10 | 15 | 60 | 0.75 | 380 | 3000 | 270 | 400 | 140 | 110 | 90 | 16 | 14 | 4 | 31 |

| SGR50-12-25 | 50 | 12 | 25 | 65 | 1.5 | 380 | 3000 | 290 | 430 | 140 | 110 | 90 | 16 | 14 | 4 | 42 |

| SGR50-8-22 | 50 | 8 | 22 | 65 | 1.5 | 380 | 3000 | 290 | 430 | 140 | 110 | 90 | 16 | 14 | 4 | 42 |

| SGR50-15-30 | 50 | 15 | 30 | 65 | 2.2 | 380 | 3000 | 290 | 440 | 160 | 110 | 90 | 16 | 14 | 4 | 45 |

| SGR50-18-40 | 50 | 18 | 40 | 65 | 4 | 380 | 3000 | 350 | 530 | 160 | 125 | 100 | 20 | 18 | 4 | 64 |

| SGR50-16-50 | 50 | 16 | 50 | 65 | 4 | 380 | 3000 | 350 | 530 | 160 | 125 | 100 | 20 | 18 | 4 | 65 |

| SGR50-24-65 | 50 | 24 | 65 | 65 | 7.5 | 380 | 3000 | 420 | 560 | 160 | 125 | 100 | 20 | 18 | 4 | 101 |

| SGR50-20-80 | 50 | 20 | 80 | 65 | 7.5 | 380 | 3000 | 420 | 560 | 160 | 125 | 100 | 20 | 18 | 4 | 102 |

| SGR65-30-15 | 65 | 30 | 15 | 65 | 2.2 | 380 | 3000 | 280 | 450 | 160 | 130 | 110 | 16 | 14 | 4 | 45 |

| SGR65-30-27 | 65 | 30 | 27 | 65 | 4 | 380 | 3000 | 310 | 540 | 160 | 130 | 110 | 16 | 14 | 4 | 68 |

| SGR65-40-40 | 65 | 40 | 40 | 65 | 7.5 | 380 | 3000 | 360 | 570 | 180 | 145 | 120 | 20 | 18 | 4 | 103 |

| SGR65-30-50 | 65 | 30 | 50 | 65 | 7.5 | 380 | 3000 | 360 | 570 | 180 | 145 | 120 | 20 | 18 | 4 | 105 |

| SGR80-35-20 | 80 | 35 | 20 | 65 | 4 | 380 | 3000 | 310 | 560 | 185 | 150 | 125 | 18 | 18 | 4 | 70 |

| SGR80-50-30 | 80 | 50 | 30 | 65 | 7.5 | 380 | 3000 | 340 | 590 | 185 | 150 | 125 | 18 | 18 | 4 | 110 |

| SGR100-40-18 | 100 | 40 | 18 | 65 | 4 | 380 | 3000 | 310 | 570 | 205 | 170 | 145 | 18 | 18 | 4 | 75 |

| SGR100-50-30 | 100 | 50 | 30 | 65 | 7.5 | 380 | 3000 | 340 | 600 | 205 | 170 | |||||