Equipment Introduction

This machine is a specialized equipment for drying semi puffed food, which can dry various shapes of food raw materials such as potato chips, french fries, spirals, shells, and crispy corners. It has a wide range of applications.

This machine uses a combustion chamber for heating and adopts a chain driven stainless steel mesh belt for transmission. And it is equipped with an advanced variable frequency speed control system, which can set different transmission speeds according to different materials. The circulating conveyor belts all use food grade specialized conveyor belts to ensure the hygiene and cleanliness of food.

This machine is equipped with advanced temperature control devices that set the drying temperature according to different materials. This machine can automatically cycle and bake materials until they meet the drying requirements. And equipped with an automatic fabric device, the material is distributed more evenly in the drying area, ensuring various drying needs of the material.

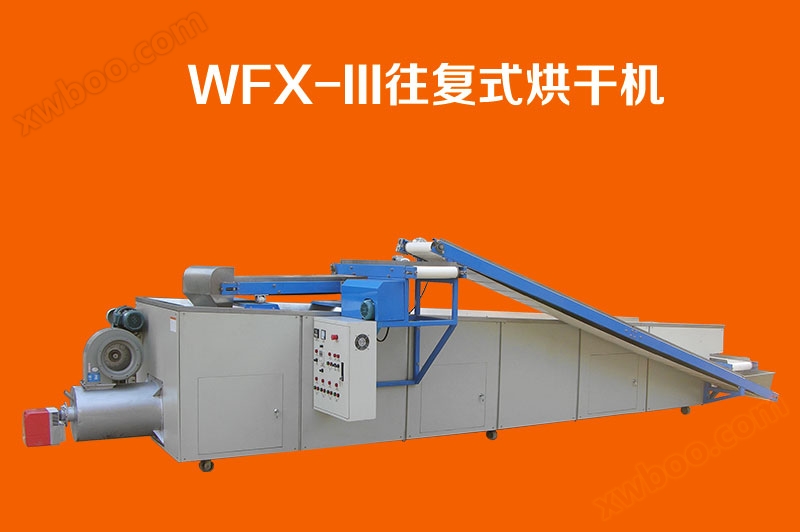

Equipment schematic diagram

Technical Specifications:

Main belt drive power: 1.5KW

Production capacity: 200-300 kg/h

Feeding drive power: 0.37KW × 4

Material feeding drive power: 0.55KW

Fan drive power: 1.5KW

Combustion energy: 100000 to 120000 kcal

Effective drying area: 6000 × 1160mm2

Width of feeding tape: 390mm

Total weight of equipment: 2100 kg

Dimensions: 7450 × 2400 × 2020mm

Installation instructions:

1. Place the equipment in a ventilated and dry place according to the location of the production line;

2. Adjust the foundation and place it steadily to prevent uneven stress on various components of the machine, which may affect the normal operation of the equipment; 3. The power supply should be equipped with a knife switch, and the equipment should have reliable grounding protection; 4. Prepare the burner oil supply device and connect the oil circuit; (Note: The distance between the fuel tank and the burner is greater than 2 meters).

Operation Instructions:

1. Before starting up, check whether all connecting parts and burner oil pipes are securely connected, whether there are any loose connections in the electrical wiring, and whether the transmission belt is clean; 2. Press the fan start button, turn on the heating knob, and set the temperature to the desired range; 3. Start the host, adjust the speed to an appropriate range, start the feeding motors I, II, III, and IV, and press the feeding start button; 4. Check if each component is operating normally and if there are any abnormal sounds;

5. After the machine runs smoothly, materials can be added for drying treatment. Once the drying requirements are met, turn off the feeding I and open the unloading knob to send out the materials.