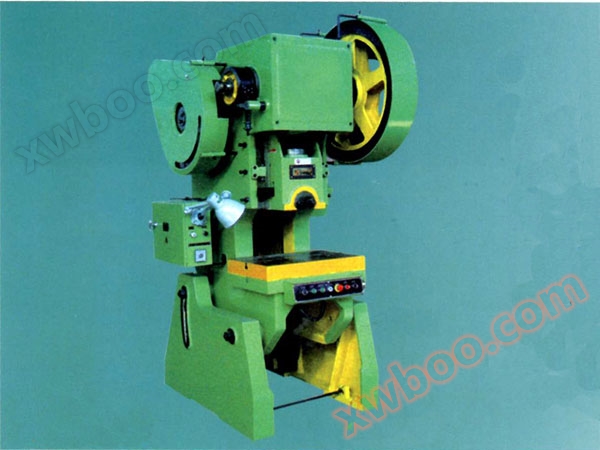

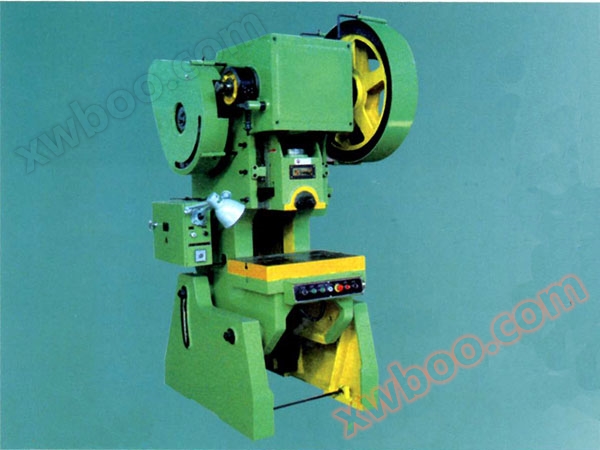

Performance characteristics:

Three beam and four column structure, optimized by computer design, simple, economical, and applicable. The hydraulic press control system adopts a plug-in valve integrated system, which is reliable in action, has a long service life, low hydraulic impact, and reduces the connection pipeline and leakage point. Unique electrical control system, reliable operation, intuitive action, and easy maintenance. Adopting button centralized control, with two operation modes: adjustment (jog) and single operation (semi-automatic). It can achieve two molding processes of fixed distance and fixed pressure, and has performance such as pressure holding delay. The work pressure and travel time can be adjusted within the specified range according to the process requirements.

Applicable fields: This series of presses is suitable for processes such as stretching, bending, flanging, cold extrusion, and punching of metal materials. It is also suitable for calibration, pressing, powder products, abrasive products, compression molding, plastic products, and compression molding of insulation materials.

Optional accessories: punching buffer device, mobile workbench, light curtain safety protection device, oil cooling device, touch industrial display screen, shaking device (hydraulic or mechanical), mold quick clamping machinery, imported PLC, floating guide rail and rolling bracket for mold replacement, overhead hydraulic system, slider locking mechanism.