VIP member

Product details

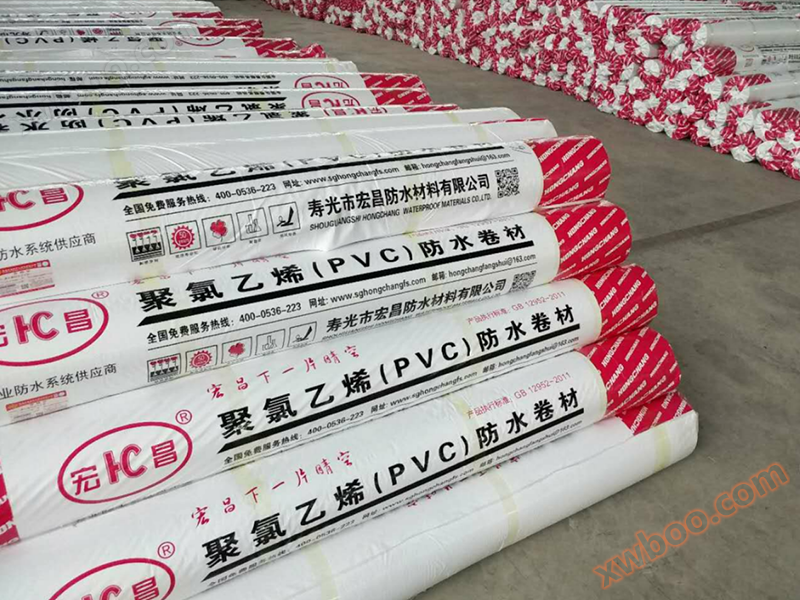

Polyvinyl chloride (PVC) waterproofing membrane

Polyvinyl chloride (PVC) waterproofing membrane is a high-performance polymer waterproofing material, mainly made of polyvinyl chloride resin. Add all kinds of special additives and anti-aging components, and use advanced equipment and advanced technology to produce. The product has the characteristics of high tensile strength, high elongation, low shrinkage, good low-temperature flexibility, and long service life. The product has stable performance, reliable quality, and easy construction.

Product Features

1. Long service life, aging resistance, roof materials can be used for more than 30 years, and underground can last up to 50 years

2. High tensile strength, high elongation, and small size change after heat treatment.

3. Good low-temperature flexibility and adaptability to changes in environmental temperature differences.

4. It has good resistance to root penetration and perforation, and can be used as a planting roof.

5. Convenient construction, welding, sturdy and reliable, and environmentally friendly without pollution.

6. Strong chemical corrosion resistance and suitable for special occasions.

7. It has good plasticity, and the processing of fine corners is convenient and fast.

8. Easy maintenance and low cost.

scope of application

1. Suitable for various roof waterproofing of industrial and civil buildings, including planted roofs, flat roofs, and sloping roofs.

2. Underground waterproofing of buildings: including waterproofing and anti-seepage of reservoirs, dams, water channels, and various parts of basements.

3. Tunnels, highways, and elevated bridges Grain depots, civil air defense projects, landfills, artificial lakes, etc.

roofing

(GB50207-2002)

(1) The strength, thickness, moisture content and other indicators of the construction base layer should meet the design requirements of national standards before PVC waterproofing membrane construction can be carried out.

(2) Determine the direction and sequence of laying the planned roll material, and arrange it naturally on the base layer according to the outline of the waterproof layer. Smooth and straight, without bending, overlap according to the required overlap width specified in the specifications.

(3) Fix according to the selected fixing method, such as mechanical fixing method, full adhesion method, strip adhesion method, etc.

(4) The overlapping parts of waterproof membrane welding should be wiped clean and dry, and hot air welding should be used. During welding, the welding nozzle should be at a 45 ° angle to the welding direction, and the pressure roller should be parallel to the welding nozzle and maintain a distance of about 5mm. The welding edge should have a bright colored molten paste seeping out, and there should be no burning phenomenon.

(5) The end of the coil is fixed with a pressure strip, sealed with sealant, and tightly sealed with cement mortar.

(6) The entire waterproof part of the project has been fully inspected and treated for quality.

underground engineering

(GB50208-2002)

(1) The strength, thickness, moisture content and other indicators of the construction base layer should meet the design requirements of national standards before PVC waterproofing membrane construction can be carried out.

(2) Reasonably select the construction method according to the different waterproof parts, and specifically implement the GB50208-2002 standard.

(3) The overlap width of the coil should be 100mm, and the upper coil should press down on the lower coil.

(4) Multiple welds should be used for lap joints, and the welding width of a single weld should not be less than 100mm.

(5) The laying of PVC waterproofing membrane should be smooth and firmly fixed to the foundation, without sagging, tension, or damage. After inspection and confirmation, the construction of the next process can proceed.

Other engineering

The application of tunnel engineering and special occasions shall be carried out in accordance with relevant national regulations.

Online inquiry