Bailian Plastic Industry PVC-U Hollow Spiral Muffler Pipe PVC-U Spiral Muffler Pipe PVC-U Muffler Pipe

Product Description:

Bailian Plastic Industry's hollow spiral sound-absorbing pipe is mainly made of rigid polyvinyl chloride (PVC-U) as the main raw material, with necessary additives added. It adopts advanced production equipment and process technology, and is extruded into a double-layer structure with several triangular spiral ribs on the inner wall of the pipe. It is a hollow wall circular pipe with reduced drainage noise. The performance of the triangular spiral ribs protruding from the inner wall of the pipe is the same as that of a solid wall spiral pipe. Due to the double-layer structure of the pipe wall, with a hollow layer in the middle, it can effectively isolate the noise generated by the water flow inside the pipe from the external transmission, and the noise reduction effect is more obvious.

Bailian Plastic IndustryPVC-UHollow spiral silencer pipe

Product feature introduction:

1. Six streamlined spiral internal ribs allow water to swirl down against the inner wall of the pipe, greatly reducing the noise of the pipeline system.

2. The outer wall of the pipe is a hollow porous structure, in which the gap layer can further block the noise generated during drainage and enhance the noise reduction effect of the pipeline.

3. Under the guiding effect of the spiral internal reinforcement of the pipe, the water flow spirals down along the pipe wall, forming a smooth air column in the center of the drainage riser, which has strong ventilation capacity and does not require additional exhaust pipes, reducing project costs.

4. The uniquely designed spiral sound-absorbing pipe fittings allow water to flow into the riser along the tangential direction, reducing water collision and thus lowering noise. This pipe fitting can also serve as an expansion joint, compensating for changes in pipeline length caused by thermal expansion and contraction.

The hollow structure on the outer wall of the pipe can provide good insulation and prevent condensation on the outer wall of the pipeline.

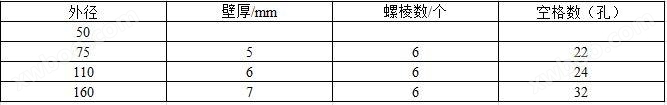

Product specifications

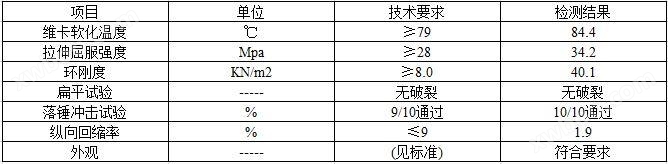

Physical properties of pipes:

Construction and installation:

The installation of the pipeline system should be carried out continuously after the wall painting is completed. When the installation is interrupted, the opening should be temporarily closed.

2. The pipeline should be equipped with inspection or cleaning ports according to the design specifications, and the position and orientation of the inspection ports should be convenient for maintenance.

3. The slope of the horizontal pipe should be set according to the design requirements. When the design does not specify the requirements, the slope of the horizontal pipe should be 0.026.

4. The distance between the outer side of the pipe fitting socket and the wall finish should be 20-50mm.

5. The installation of the pipeline system shall comply with the provisions of CECS185:2005 "Technical Specification for Hollow Wall Silencing Hard Polyvinyl Chloride Pipe Engineering for Building Drainage".

After determining the length of the pipe, a steel saw or circular saw blade can be used, and the sawing machine can cut it. The cuts at both ends should be kept flat, and the burrs should be removed and chamfered with a butterfly file. The chamfer should not be too large.

7. When using our company's spiral silencing specialized pipe fittings, attention should be paid to the direction of the rubber ring pressing ring during installation.

8. Remove oil stains and debris from the pipes to keep the joint area clean.

9. The depth of insertion of the pipe end into the joint should be determined by the design. After the insertion depth is determined, a trial insertion should be carried out and a mark should be drawn on the surface of the pipe mouth as required.

10. Insert the pipe end straight into the socket to the bottom of the socket, then pull it out to the marked position, install the nut and tighten it. When tightening, the degree of force should be controlled to prevent the nut from cracking.

Scope of application:

Suitable for indoor noise reduction and drainage systems in high-end office spaces, clubs, hotels, guesthouses, apartments, villas, and upscale residential communities.