The steam shrink machine is an important equipment in the modern packaging field, providing efficient, aesthetically pleasing, and reliable packaging methods for products.

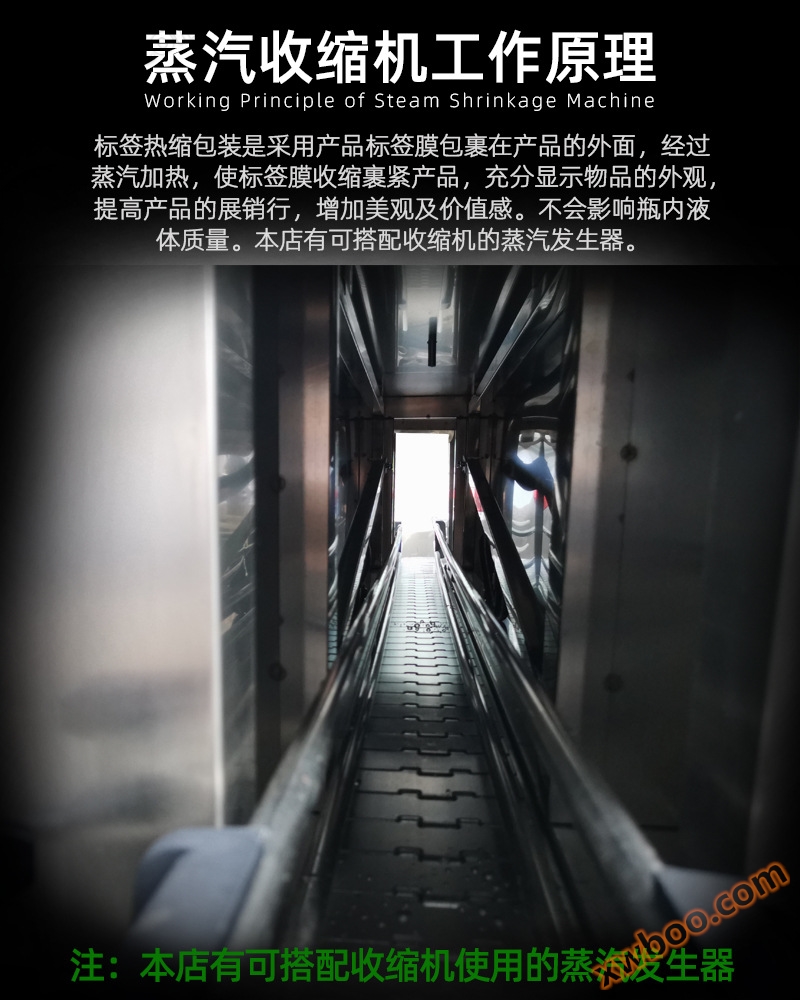

The workflow usually involves first placing the product into pre processed packaging materials, and then sending it into a shrinkage chamber filled with high-temperature steam through a conveying device. Under the action of steam, the packaging material rapidly shrinks and tightly adheres to the surface of the product.

There are many advantages to steam shrink machines:

- Tight shrinkage: It can make there almost no gap between the packaging and the product, providing good protection and fixation. For example, in the packaging of glass products, it can effectively prevent them from shaking and being damaged during transportation.

- Flexible operation: Parameters such as steam temperature, pressure, and conveying speed can be flexibly adjusted according to different product and packaging requirements.

- Easy maintenance: The equipment structure is relatively simple, and daily maintenance and upkeep are relatively easy, reducing the cost of use.

When choosing a steam compressor, there are several key considerations:

- Product characteristics: including material, weight, fragility, etc. For example, for fragile ceramic products, it is necessary to choose a machine with a milder shrinkage process.

- Production scale: If it is large-scale continuous production, it is necessary to choose models with high production capacity and good stability.

- Site conditions: Ensure that the size and installation requirements of the machine match the actual site.

Steam shrink machines play an important role in the field of product packaging, providing strong support for enterprises to enhance their product image and market competitiveness.