System Overview

The PCYS-02 Tank Farm Monitoring and Management System is a new generation of tank farm monitoring and management system designed by our company to achieve unified automatic management of storage areas and tank farms in industries such as petrochemicals, as well as on-site equipment safety automation control. The system mainly completes daily production operations, safety protection, operation management, and scientific production scheduling in tank farms.

By using the irrigation district monitoring and management system, it is possible to collect and process various relevant data of materials stored in storage tanks in real time through hardware integration and software programming in the warehouse or tank area. Various management reports related to storage capacity, density, revenue and expenditure can be printed according to specific needs; By configuring, monitoring, and controlling relevant equipment and process parameters in real-time, and through a network communication system, management personnel at all levels can have real-time understanding of the storage revenue, expenditure, and sales situation of each warehouse and tank area. The application of the tank area monitoring and management system greatly improves the automation management and operation capabilities of the storage area and tank area, removes and reduces unnecessary intermediate links, strengthens internal management, and improves overall operational efficiency, thereby achieving economic, rational, and efficient operation of the entire system.

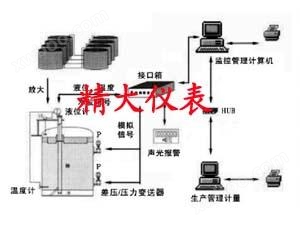

■ System composition (as shown in the following figure)

The PCYS-02 tank farm monitoring and management system is mainly composed of high-performance and high reliability industrial control computers (IPC), data acquisition and control units (ADAM or PLC), and various on-site instruments, which are organically combined to achieve the sharing and coordination of signals in various parts, and to complete comprehensive measurement, control, and management functions. The system is suitable for process management and control of various storage and transportation equipment in the tank area, and is used to complete the process parameter detection and display of the tank area data collection and management system, equipment status detection and display control, and information storage, retrieval, and printing of reports.

System functions (software structure as shown in the following figure)

1. Processing collection and processing: It can measure real-time parameters such as liquid level, interface, temperature, density, volume, weight, on-site combustible gas concentration, valve and pump status of each storage tank. The output signal of the detection instrument, whether it is an analog signal or a 485/232 serial output signal, can be input to the computer through a signal collector and then processed accordingly.

2. Display and alarm function: The display screen dynamically displays bar charts of the liquid level and water level of each storage tank. When the liquid level or water level exceeds the set value, the horn connected to the operation site will issue a voice warning to remind the operator to pay attention.

3. Database management function: The database is an important component of the system management software, which includes the monthly database, historical database, system parameter database, and savings volume table database. After the data in the monthly database exceeds the specified time, it will be automatically transferred to the historical database. During the system operation, various databases can be queried, deleted, saved, or printed.

4. Report printing function: Various report formats and contents are developed according to customer requirements, and report output is divided into two printing output methods: automatic timed and manual random.

5. Operation protection function: It mainly prevents unauthorized personnel from operating the monitoring system. The system has alarm prompts for incorrect operations, and password protection function is provided for important operations.

6. Online parameter adjustment function: The system can easily and conveniently authorize online modifications to various information of monitoring points, such as range, upper and lower limits, units, migration amounts, etc.

7. PID regulation function: regulating and setting various process parameters including PID.

8. Network communication function: The system can use two standard configured PCs as detection and management computers, one placed in the on-site monitoring room and the other in the business management room. The two computers are connected through local area networks, allowing management decision-makers to understand and manage the operation and production of storage tanks at any time.