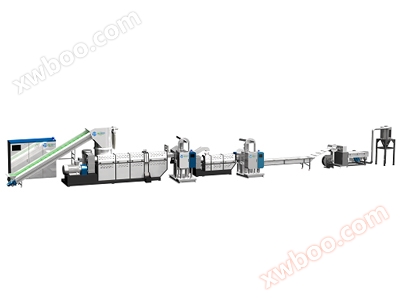

Non woven dual stage plastic granulator

Name: Non woven Double stage Plastic Granulator

Raw materials: non-woven fabric, polyester fiber fabric, nylon fiber, polyester waste fabric

Usage:

Operation flowchart

Product Features

The non-woven dual stage plastic granulator is used to recycle, granulate and reuse waste, scrap, scraps, defective non-woven fabrics, polyester fiber fabrics, nylon fibers, etc., making their waste plastics renewable and recyclable.From feeding, crushing, conveying, to granulation, the extruder can choose between exhaust holes or no exhaust holes according to the characteristics of the material. The granulation method adopts a pulling strip cutting method, a single board dual station screen changing device, no downtime, and a large filtration area.

model |

PTCS80 |

PTCS100 |

PTCS130 |

PTCS150 |

PTCS185 |

|

screw diameter (millimeters) |

80 |

100 |

130 |

150 |

185 |

l/d |

18-42 |

||||

|

rotation speed (rpm) |

10-150 |

||||

|

output (kg/hour) |

150250 |

200-350 |

450600 |

600-700 |

800-1200 |

model |

PTCS Three in one plastic recycling machine |

final product |

plastic pellets |

Recycling machine structure |

Conveyor belt, crushing cylinder, extruder, granulation unit, water cooling unit, drying unit and storage cylinder, degassing unit, filtration unit |

Recyclable materials |

HDPE, LDPE, LLDPE, PP, BOPP, CPP, OPP, PA, PC, PS, PU, EPS |

production capacity |

100kg~1200kg per hour |

Feeding system |

Belt conveyor belt, clamp wheel set (optional) |

screw diameter |

65-180mm (customized) |

screw length-to-diameter ratio |

30/1, 32/1, 34/1, 36/1 (customized) |

Screw material |

38 chromium molybdenum aluminum Or bimetallic |

Dewatering pores |

Double vent, single vent or no vent (customized) |

filtration system |

Dual column filtration |

Granulation type |

Hot die head cutting type (water ring cooling) |

cooling method |

water cooling |

voltage |

Customization (e.g. 480V 60Hz in the United States, 440V/220V 60Hz in Mexico, 380V 60Hz in Saudi Arabia, 415V 50Hz in Nigeria) |

Optional accessories |

Metal detector (S+S Germany), clamp wheel set, color masterbatch and additive meter, centrifugal dehydrator |

delivery period |

Customized machines are required50~70 days. |

Warranty period |

a year |

after-sales service |

Engineers can be dispatched to customers' overseas factories to assist with machine installation |

Feeding Unit 1

Belt conveyor unit: Recycled waste can be directly placed on the conveyor belt for easy feeding,Conveyor belt controls feed rate quantitatively in amperes

Feeding Unit 2

Clamp wheel set: can be paired with a belt conveyor unit to simultaneously feed the entire roll of film on the material rack.

Dewatering pores

squeezeThe dual air outlet design can release more ink and moisture from recycled materials to improve the quality of the final product

Filter and screen replacement system

The double column screen changing system has twice the filtering area as the general pallet screen changing system. This mesh changing system can improve filtering efficiency and reduce the number of mesh changes. In addition to reducing the number of screen changes, the dual channel design allows the machine to operate continuously during the screen change process, increasing the total production capacity of the machine and reducing waste generation.

Cutting and compacting system

Equipped with precise temperature control and cutting system, ensuring that semi molten plastic can enter quickly and stablysqueezePerform mixing and fusion in the system.

Particle cutting unit-Strip cutting system

The strip cutting system includes a cooling water tank, strong wind drying, and a cutting machine. The cooling water tank is used to cool the plastic strips pulled out by the extruder.

product

The recycled particles can be 100% directly put into the blown film machine or pipe materialsqueezeReusing the production line.

High security protection: safeguarding personnel and equipment safety

Emergency stop protection (used for stopping equipment in case of emergency)

limit switch

Protective cover shell

Warning reminder for high-speed transmission components (yellow paint, label)

Lower energy consumption, higher output

By relying on specially designed control schemes and process monitoring, lower energy consumption requirements can be achieved

Obtain higher output under the same equipment specifications, improve the energy consumption ratio of output, and quickly recoup costs

one-stop service

Provide a complete solution: factory design, equipment and auxiliary machinery, and a fast response service system (online+offline)

SMART intelligent control

HMI PLC control: Ergonomic touch screen, easy to operate, high stability, low maintenance cost in the later stage

Formula Memory: By setting parameters based on the formula and logic of different materials, it is easy and convenient to load and save process parameters from the formula storage system, making recycling easier

Remote diagnosis and data transmission: Combining Bluetooth and modules to achieve remote data transmission and monitoring, fast diagnosis

Preheating: Set the program according to the material formula and preheat the equipment in advance to save labor

Copyright reserved. Infringement will be prosecuted