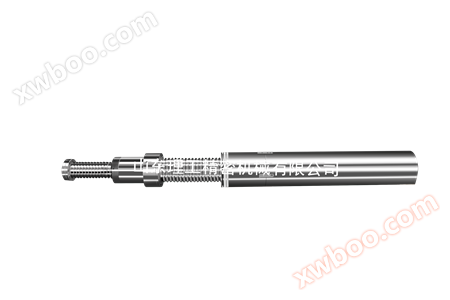

The multi-stage synchronous screw push rod mechanism has a small size but can achieve large stroke transmission. It can achieve high-precision extension and contraction of about n times its own length, and can achieve synchronous and same speed extension and contraction of multi-stage ball screws. It has the characteristics of high transmission accuracy, compact structure, small space occupation, simple operation, convenient use, and low noiseIt also combines the efficient transmission efficiency of ball screws, solving the disadvantages of high failure rate, multiple safety hazards, and tedious maintenance of traditional telescopic equipment.

All ball screws are connected sequentially through sliding spline heads and tails. Each ball screw is fitted with a screw nut, and a connecting cylinder is connected to the screw nut. The connecting cylinder is threaded into the outer cylinder corresponding to the ball screw. The connecting cylinder is also fixedly connected to the outer cylinder corresponding to the adjacent ball screw. The head end of the first ball screw serves as the input end, and the tail end of the outer cylinder corresponding to the last ball screw serves as the output end. By cascading multiple ball screws, the lifting stroke of the load is increased. Two adjacent ball screws are connected by sliding splines, which ensures the stability of the ball screw structure during expansion and contraction, avoids bearing biased loads, and ensures the safety of the device when lifting loads.

This structure is widely used in multi-stage electric cylinders and large spacecraft with small internal spaces that require stable load-bearing and synchronous transmission of telescopic mechanisms.