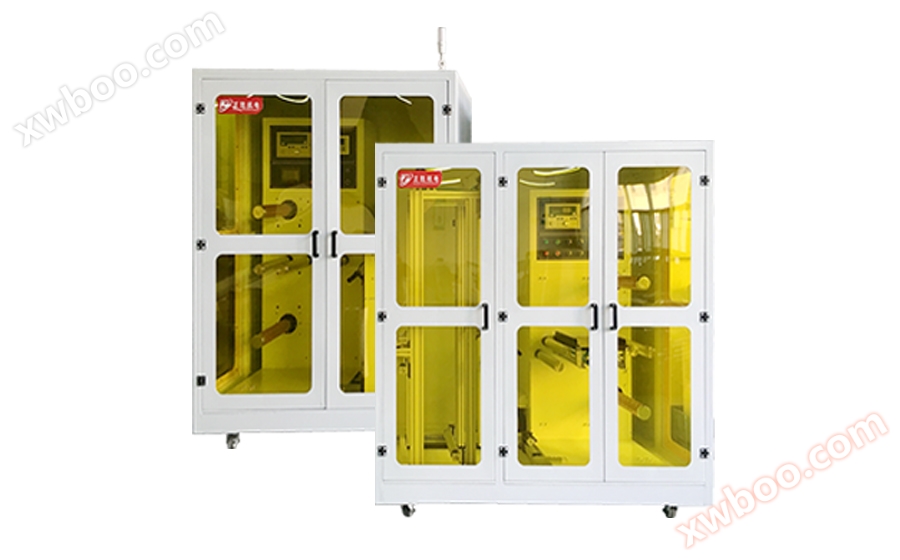

1Equipment Overview

The multifunctional material feeder is used in the roll to roll process to automatically feed the roll material to downstream equipment for processing,Automatically transfer the previous sectionThe long strip material sent out by the device is automatically folded into a roll shape.

IIMaterial dispenserSpecifications and main technical indicators

1. Applicable width: Material width of 400mm, single row feeding.

2.Applicable material size: Material with large outer diameter400mm, Material inner diameter 3 inches(Used in conjunction with gas curtain shaft)

3. Applicable material thickness: 0.05~0.1mm

4. Conveyor surface height: 400mm

5.Product Quality Standards:No strain found after feeding,Crease,Scratches and missing corners.

◆Equipment function configuration

1.Material axisTwo 3-inch discharge air curtain shafts.

2.Loading methodThe air curtain shaft adopts a suspended wall installation design, and the material is loaded from one side in front

3.Fixed methodThe gas curtain shaft adopts a rotating joint, which is matched with an electromagnetic valve to automatically inflate and fix the material

4.Material torsionEquipped with one set of automatic tension controllers, combined with tension detection rollers,Automatic adjustment brakedischarge

Axial torqueMake the surface tension of the material uniform

5.Material receiving methodEquipped with one set of material receiving platform, the platform uses vacuum adsorption to evenly adsorb the material ontoflatOn stage, on stage

The material is clamped using pneumatic clamps to prevent displacement during cutting,Easy to use tape to connect the material head to the material tail

connect.

6.Material release cacheEquipped with one set of feeding buffer zone, when the material is sent to the tail,Tail and next rollThe material head isconnect

Docking on the material platformCannot continue to distribute materials, buffer zone materials can continue to be distributed,So that there is no need to accept materials, resulting in the entire line

Pause

7. Material testing: Two sets of gas curtain shaft material testing, testing the outer diameter of the material. When it is less than the fixed outer diameter,Beep alarm,

Prompt to prepare the next roll of materials for receivingMaterial testing on the receiving platform*1 group,When there is no material detected, the pneumatic clamp

Activate, clamp the material tail tightly, and wait for manual operationThe next roll of material will be receivedBuffer photoelectric upper limit detection

know*1 group, when the buffer material is used up,The material reception has not been completed yet. Send a signal to the downstream equipment to stop receiving the material

8. Material alignment:be equipped with1 set of automatic correction device, combined with ultrasonic detection and photoelectric detectionAutomatic correction and placement

VolumeEnsure that materials are placed in a straight line.

9Machine structure: The entire machine adopts steel plate processing and welding, followed by high-temperature spray coating treatment for the skeleton, and other partsironusechrome plating

The aluminum parts are treated with anodized black treatment, and the surrounding sealing plates and shafts are installed with lubricationsealhandle.

IIIBuffer machineSpecifications and main technical indicators

1. Add a buffer machine at the middle section of the etching line to prevent deviation and stretching caused by excessive materialThe function.

2. Applicable width: Material width of 400mm.

3. Transmission method: Two sets of material pulling rollers are used, with the front roller returning its pulling force and pulling the material forward,Rear roller from

With tension, keep the material taut and evenly tensioned.

4.Applicable material thickness:0.05~0.1mm conveying surface height: 1000mm

5. Product quality standards: After receiving the material, there should be no signs of pulling, wrinkling, scratching, or missing corners,The end face of the coil material is neat.

6. Machine structure: The entire machine adopts steel plate processing and welding, followed by high-temperature spray coating treatment for the skeleton, and other partsIron miningUsing plating

Chromium treated aluminum parts are treated with anodized black treatment, and the surrounding sealing plates and shafts are lubricated and sealed for installation.

Material receiving machineSpecifications and main technical indicators

1. Applicable width: Material width of 400mm.

2. Applicable material size: Material with a large outer diameter of 400mm and an inner diameter of 3 inches (used in conjunction with an air curtain shaft)

3. Applicable material thickness: 0.05~0.1mm

4. Conveyor surface height: 1000mm

5. Product quality standards: After receiving the material, there should be no scratches, creases, scrapes, or missing corners, and the end face of the rolled material should be neat.

◆ Equipment function configuration

1.Receiving shaftTwo 3-inch discharge air curtain shafts.

2.Loading methodThe air curtain shaft adopts a suspended wall installation design, and the material is loaded from the front side on one side.

3.Fixed methodThe gas curtain shaft adopts a rotating joint, which is matched with an electromagnetic valve to automatically inflate and fix the material

4.Receiving torqueEquipped with one set of automatic tension controllers, combined with tension detection rollers, automatically adjust the magnetic fieldFenliClutch

The winding torque is matched with the winding motor for windingMake the surface tension of the material uniform

5. rollingEPC: equipped with 1 set of automatic correction device, combined with ultrasonic detection photoelectric for automatic correctionentangleCollecting the roll,

The material ends must ensure a neatness of ± 1mm

Material testing2 sets of material testing for air curtain shafts, testing the outer diameter of the materials. When the outer diameter is greater than the fixed outer diameter,Beep beepcall the police, mention

Switch the winding reel.

Feeding method: The entrance position is equipped with a set of silicone rollers, which are coordinated with a servo motor to uniformly move upstreamset upPrepare materials for delivery

Get out.

Machine structure: The entire machine adopts steel plate processing and welding, followed by high-temperature spray coating treatment,Other parts are made of chrome plated iron

The aluminum parts are treated with anodized black treatment,Install the sealing treatment around the sealing plate shaft.