Mobile Intelligent Inspection Scheme for Distribution Drones

1、 Background of the plan

1.Background and Requirements

(1)Industry demand:The demand for unmanned aerial vehicle inspection of distribution lines mainly stems from the limitations of traditional manual inspection methods, as well as the urgent need for efficient, safe, and intelligent operation and maintenance in the power system.

(2)Technical requirements:Stable flight, with obstacle avoidance ability, avoiding collisions with wires or obstacles; Intelligent functions, autonomous route planning, and one click inspection.

(3)Operational requirements:Simplify operations, adapt to non professionals, and provide automated task modes; Rapid deployment, line inspection, and quick transition.

(4)Data management requirements:4GOr self-organizing network communication, real-time video or inspection data real-time feedback; Automatic data archiving and system integration.

(5)Security requirements:Drone security access, identity authentication; Data encryption transmission to prevent leakage.

(6)Environmental adaptation requirements:Adapt to various environments such as urban areas, mountainous areas, and farmland; Multi machine collaborative operation improves the efficiency of line inspection.

2.general idea

Through the application of mobile intelligent patrol terminal that can be flexible and responsive, combined with docking UAV autonomous patrol micro application, one button autonomous patrol, edge computing and lightweightAIModel, Build 'Inspection Plan'-Task distribution-Accurate homework-The full process loop of data archiving and return. The mobile intelligent inspection terminal relies on intelligent application terminals, edge computing power, and secure link communication to achieve mobile autonomous grid inspection coverage in multiple scenarios and environments, greatly improving the coverage capability and emergency response efficiency of remote areas, reducing the dependence on professional personnel, and promoting the intelligent upgrade of power distribution inspection.

2、 Scheme design

1.System Architecture

2.Key Product Functional Architecture

3.Key Features

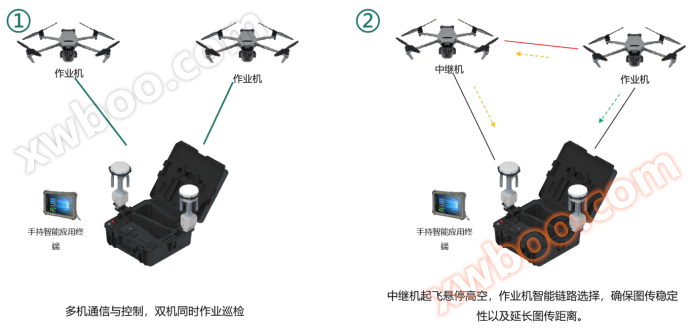

(1)multi-aircraft cooperation

(2)secure access

The mobile intelligent inspection terminal is equipped with a security access module, which meets the security protection requirements of State Grid for unmanned aerial vehicle business application data: two-way identity authentication and encrypted operation data flow.

(3)Relay networking

In the presence of mountains and buildings obstructing the environment, the operational capabilities of drones are greatly limited. Through relay networking or flexible relay services, the operational capabilities and scope of drones in inspection and emergency rescue scenarios can be effectively improved.

The mobility of mobile intelligent inspection terminals and the combination of terminals and relays can effectively improve the coverage radius of drones.

(4)Autonomous obstacle avoidance and obstacle avoidance

pass throughAIThe combination of visual technology and LiDAR perception detection technology enables the detection of obstacles such as overhead wires and hollow trees. After detecting obstacles, the flight strategy is dynamically adjusted based on autonomous obstacle avoidance and obstacle avoidance technology to avoid obstacles, further ensuring the safety of drone flight operations.

Obstacle avoidance technology is based on autonomous obstacle avoidance technology, further realizing autonomous navigation and path planning of unmanned aerial vehicles in complex environments.

4.key technology

(1)Tower target recognition

Realize tower identification (transmission) based on real-time video from unmanned aerial vehicles through the intelligent terminal built-in in the mobile intelligent inspection terminal/The distribution tower and direction positioning are achieved, and the drone is controlled to fly at a fixed point through intelligent terminals, ultimately realizing automatic flight along the line direction and real-time identification of the tower.

The implementation of the above key technologies can be used for intelligent collection of tower ledger information, intelligent planning of tower routes, and other applications.

(2)Adaptive inspection

Adopting model lightweight processing technology to deploy complex neural network models to airport intelligent terminals in a lightweight manner,AIAbility prerequisite, realizing adaptive inspection of distribution towers.

(3)video compression

Relying on intelligent video encoding andAIPerception recognition technology, using video imagesAIMultiple comprehensive algorithms such as perceptual compression, video restoration, and video enhancement can compress the bitrate of high-definition videos, achieving100KbpsClear and smooth access under narrow bandwidth conditions.

3、 Key product functions

1.One click self inspection

The mobile intelligent inspection terminal business system is integrated with unmanned aerial vehicle autonomous inspection micro applications, automatically obtaining inspection tasks and inspection routes. Operators can quickly start inspections with one click at the work site. After the inspection is completed, the intelligent terminal automatically completes data archiving, supports online or offline feedback, and can also perform lossless compression on the returned images. Supports single machine inspection mode, relay inspection mode, and multi-level inspection mode.

2.Remote monitoring

Mobile intelligent inspection terminal support4GThe remote live broadcast of real-time drone images and remote monitoring of real-time locations are achieved through feedback and lossless video compression, which facilitates remote management and command of drone inspection operations.

3.Intelligent calibration of navigation points for distribution towers

Distribution line towers are generally planned for routes through waypoint marking. The mobile intelligent inspection terminal has a built-in business system based on tower recognition algorithm, which can automatically perform intelligent waypoint calibration on a certain section of distribution line towers, reducing the complexity of waypoint planning through manual teaching and lowering the technical requirements for operators.

4.Intelligent collection and verification of tower ledger

The mobile intelligent inspection terminal is equipped with a built-in business system to connect and obtain the tower foundation ledger. At the same time, based on the tower recognition algorithm, it automatically collects tower information of transmission and distribution lines, including tower type, latitude and longitude, and height. The collected information is compared with the existing information in the ledger to see if it is consistent, and can be manually reviewed to update the ledger data.

5.Data archiving

After the drone inspection operation, the collected data is sorted and archived, mainly including: associating inspection images with towers or equipment, automatically naming images as inspection objects, classifying images by defect types, and classifying images by task operations.

4、 Key product advantages