-

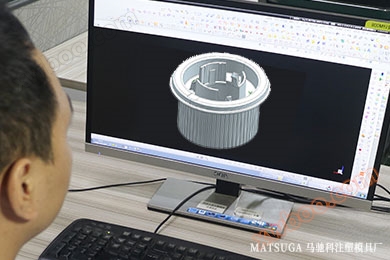

Optimization of Injection Molding Product Structure

Optimization of Injection Molding Product Structure

-

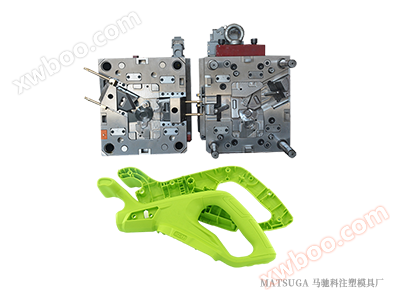

Plastic injection mold processing

Plastic injection mold processing

-

Plastic injection mold processing

Plastic injection mold processing

-

Injection mold manufacturing and processing

Injection mold manufacturing and processing

-

Injection mold processing workshop

Injection mold processing workshop

-

Machike Injection Mold Factory

Machike Injection Mold Factory

-

Mold processing CNC machining

Mold processing CNC machining

-

Mold processing and spark machining

Mold processing and spark machining

-

Mold processing line cutting processing

Mold processing line cutting processing

-

Mold processing and grinding machine processing

Mold processing and grinding machine processing

-

Mold processing and milling machine processing

Mold processing and milling machine processing

-

Mold processing production workshop

Mold processing production workshop

-

Plastic mold for vacuum cleaner housing

Plastic mold for vacuum cleaner housing

-

Injection mold for lithium battery casing

Injection mold for lithium battery casing

-

New energy shell plastic mold

New energy shell plastic mold

-

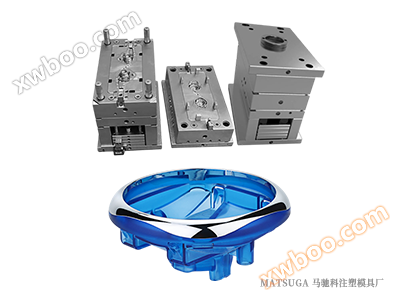

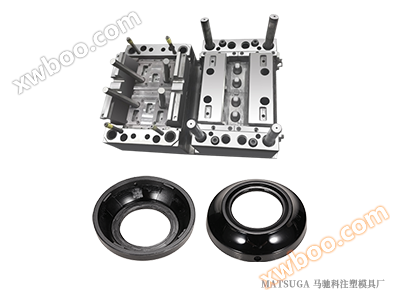

Injection mold for electroplated parts

Injection mold for electroplated parts

-

Plastic mold for air conditioning electroplating parts

Plastic mold for air conditioning electroplating parts

-

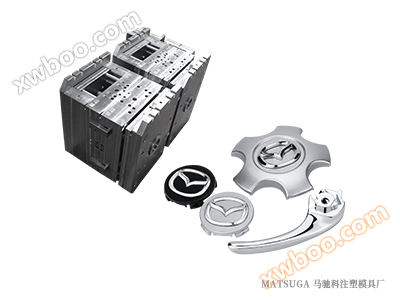

Plastic molds for automotive parts electroplating parts

Plastic molds for automotive parts electroplating parts

-

Plastic shell injection mold

Plastic shell injection mold

-

Automotive interior plastic molds

Automotive interior plastic molds

-

Injection molded parts shell plastic mold

Injection molded parts shell plastic mold

-

Laptop shell injection mold

Laptop shell injection mold

-

Top box shell injection mold

Top box shell injection mold

-

Display box injection mold

Display box injection mold

-

Why do customers choose Machico for outsourcing processingServices you need we all provide

Since its establishment 10 years ago, Dongguan Machike Precision Products Co., Ltd. has mainly exported customized products for Japanese household appliances, home beauty devices, and maternal and child products, accumulating experience in product research and development, mass production management, quality management, and other areas. Machico factory has always adhered to original design to provide customers with one-stop manufacturing solutions including appearance design, sample production, circuit development, structural design, mold design, mold processing, injection molding, two-color injection molding, encapsulation injection molding, finished product assembly, reliability testing, size measurement, etc. -

-

Mold making, sample trial production, mass production, finished product packaging, shipment, and full process quality supervision

-

Why do customers trust the quality of Machico so muchmatsuga Processing quality

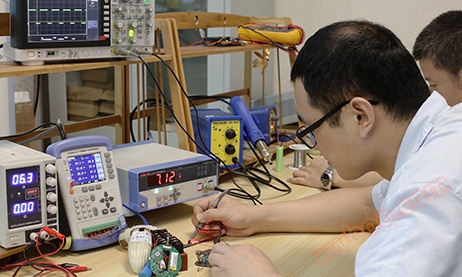

Dongguan Machike Precision Products Co., Ltd. has a total of 136 reliability experiment size measurement equipment, which can provide customers with material selection and product structure optimization before mass production. Whether it is finished product customization or mold injection molding, these devices can be used to verify whether the mass production solution is appropriate. The production process strictly follows the ISO9001, ISO14001, IATF16949 management system, and the reliable experimental size measurement equipment can provide accurate data support. With high quality, fast delivery, and zero returns, it has won the trust and support of customers.

Reliability Laboratory of Machico FactoryWe have 41 reliable experimental equipment, including high and low temperature cyclic cold shock testing machines, yellowing resistance testing machines, salt spray testing machines, environmental life testing machines, and simulated vehicle transportation vibration testing machines.

Measurement Room of Machico FactoryWe have 95 measuring devices for dimensions such as 3D, projector, micrometer, depth gauge, caliper, hardness tester, plug gauge, and block gauge.

-

dimensional measurement

-

High temperature resistance test

-

Weather resistance test

-

Wear resistance test

-

3D measurement

-

Visual inspection

-

-

Do customers trust the outsourcing capabilities of Machico?Services you need we all provide

Injection mold processing at Machico factoryWe have 128 CNC machining machines, spark machines, wire cutting machines, lathes, milling machines, grinders and other equipment, 8 mold engineers, 23 mold manufacturing teams, and an annual output of 350 sets of molds. We undertake injection molds, vertical encapsulated injection molds, and two-color injection molds.

Injection molding processing at Machico factoryWe have a total of 35 single and dual color, vertical and horizontal injection molding equipment ranging from 35 tons to 550 tons. Among them, there are 24 horizontal single color injection molding machines of 90 tons, 120 tons, 160 tons, 260 tons, 320 tons, and 480 tons, 4 dual color injection molding machines of 260 tons, 360 tons, and 550 tons, and 7 vertical injection molding machines of 35 tons, 85 tons, 160 tons, and 260 tons. Undertake injection molding processing, vertical encapsulation injection molding processing, and two-color injection molding processing.

Finished product assembly at the Machico factoryWe have 13 assembly production lines and 2 automated assembly clean rooms. Our finished products exported to Japan include household small appliances, home beauty devices, and maternal and child products; Customized products for e-commerce companies, cross-border e-commerce, and foreign trade companies include phone cases, sports equipment, beauty devices, lighting fixtures, pet supplies, 3C Bluetooth wearables, mosquito lamps, night lights, humidifiers, juicers, breast pumps, milk warmers, bottles, storage bottles, milk mixers, and other products for mold opening injection molding and finished product assembly.

-

-

01Optimizing and evaluating product structure using CAE technology

02Is the design of electronic components and thermal sensitive materials reasonably evaluated

03Evaluate whether the selection of components and materials is reasonable for the internal heat dissipation of the product

04Evaluation of vibration attenuation characteristics of materials such as plastics, hardware, adhesives, leather, glass, paper, etc

05Analyze and improve the mechanical action of the product

06Improvement of 3D simulation action analysis for electronic mechanism components

07Improvement and Analysis of Abnormal Sound, Noise, and Vibration in Mechanism Linkage Components

08Diagnosis and evaluation of process equipment to provide a reasonable renovation plan

09Using CAE technology to analyze and improve surface processing such as oil spraying, electroplating, nano coating, vacuum electroplating, printing, etc

| Experimental analysis materials | metal | composite material | plastic | polymer | |

| Wood and paper | organic matter | ingredients | ceramics | ||

| fiber | Electrical and Electronic | other | |||

| Experimental analysis content | Construct analysis | surface analysis | Quantitative: Qualitative analysis | Biological analysis | |

| Biological analysis | The nature of heat | Electrical properties | Optical properties | ||

| anti-fatigue | length | Impact resistant and fatigue resistant | |||

| Wear-resistant | roughness | hardness | hardness | granularity | |

| Weather resistant perishable food | Crack test | other | |||

-

Prototype handmade creation

-

Original appearance design

-

Micro scale 3D printing

-

Electronic circuit development

-

Injection mold design

-

Injection mold workshop

-

Injection molding workshop

-

Two color injection molding workshop

-

Liquid silicone system

-

Vertical machining workshop

-

Automated assembly machine

-

Finished product assembly workshop

-

Online Consultation

-

requirements communication

-

design proofing

-

sample acceptance

-

sign a contract

-

after-sales service

-

Logistics delivery

-

pay in full

-

Inspection packaging

-

mass production