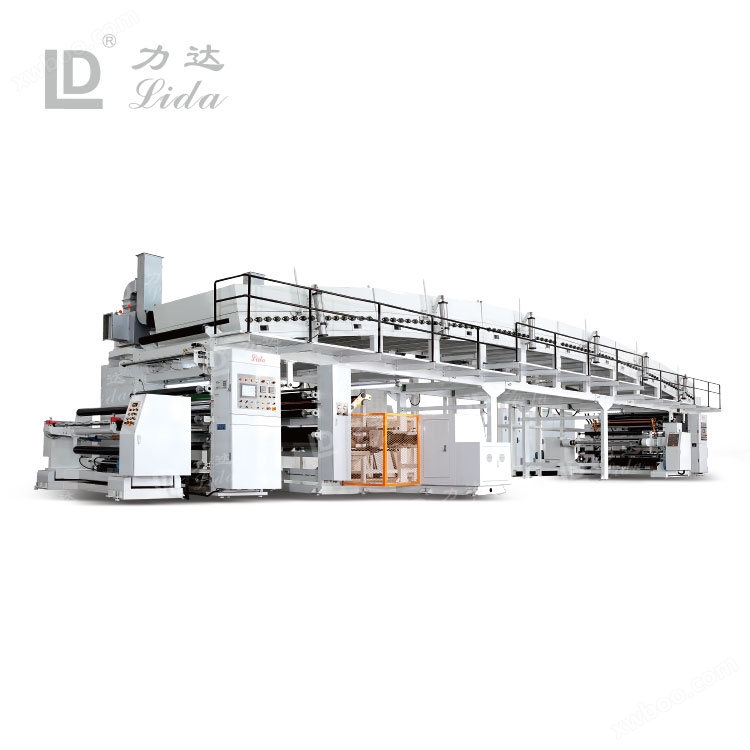

Main structural features:

Main structural features:

Unwinding: independent tower type dual station unwinding rack, automatic cutting for changing rolls, pneumatic shaft with safety clamp for loading and unloading rolls, unwinding EPC device.

Roll up: Independent tower type dual station material rack, flying knife cutting, surface winding form, constant tension winding.

Glue application: The wire roller is used for gluing, and the uniform rubber roller is driven by an independent motor with pneumatic reset.

Oven: Six stage top opening high constant temperature drying oven, the entire oven adopts negative pressure design, and hot air does not blow out of the oven. High air volume and high air pressure can create a low-temperature and high wind speed drying method. The guide roller is driven by a separate motor and driven by a synchronous belt, resulting in low noise.

Composite: Three roll composite pressure roller device, ensuring uniform pressure force across the entire surface; S-shaped dual cooling roller.

Whole machine: PLC programmable controller is used for logic control and protection, four stage closed-loop tension control and display, and the transmission system is fully adopted

Main technical parameters:

| Coating substrate | Roll materials such as plastic film and paper |

| Maximum mechanical speed | 200m/min |

| Composite width | 850,1050,1250,1450,1650mm |

| Maximum winding and unwinding diameter | Ф800,Ф1000mm |

| coating | Wire roller, micro concave, comma scraper (optional) |

| drying method | Electric heating, steam heating, thermal oil heating, or gas heating |