KHR3000T High Altitude Automatic Digital Rockwell Hardness Tester

Product Features:

The maximum vertical testing space is 430mm (or 450mm), with a throat depth of 200mm, making it particularly suitable for measuring medium and large parts. Widely used in industrial fields such as metallurgy, forging, casting, petroleum pipelines, and petroleum drilling tools

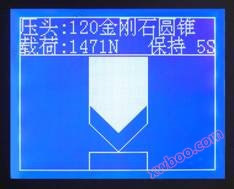

Upgrade to automatic switching test force. Screen buttons select the ruler, automatically recognize and switch to the correct test force, completely avoiding human error operation

Automatic digital Rockwell hardness tester, capable of automatically measuring Rockwell hardness

The indenter extends 200mm horizontally and can test surfaces that cannot be measured by ordinary hardness testers, such as the inner surfaces of ring-shaped, tubular, and frame parts, and the base

Fully functional, capable of testing 15 Rockwell hardness standards, including plastic Rockwell hardness

Loading, holding, and unloading are precisely controlled by computers to accurately meet the latest national standards and ASTM standards

Bilingual menu in Chinese and English, large screen, high-definition, high brightness backlit dot matrix LCD display screen

The keyboard operation is simple and clear, easy to learn and use

HB, HV, HLD, HK multiple hardness system conversion and tensile strength conversion

500 sets of measurement data, testing time, and testing sequence numbers are automatically stored for easy access or printing at any time

Equipped with dual communication ports of USB and RS232, it can be connected to an external printer; Or transmit the test results to the computer

Meets all international Rockwell hardness testing standards, including American standard ASTM E-18, international standard ISO6508, EU standard BS EN6508, and Chinese standard GB/T230.2

Functions and indicators:

Complete measuring scales: capable of performing Rockwell measurements HRA、HRB、HRC、HRD、HRE、HRF、HRG、HRH、HRK、HRL、HRM、HRP、HRR、HRS、HRV There are 15 types of rulers for measurement, covering various hardness ranges of materials such as hard alloys, quenched steel, alloy steel, soft steel, copper, aluminum alloys, engineering plastics, artificial wood boards, etc

Automatic control of the experimental process: Loading, holding, and unloading are precisely controlled by a built-in computer to accurately meet the latest national/international standard requirements. The entire testing process is fully automated, eliminating human interference and errors.

Powerful data processing function: 500 sets of test time, serial number, and test results are automatically stored, which can be called, viewed, and printed at any time, and cannot be changed. Effectively monitor the testing history to ensure the objectivity and fairness of historical data.

Tolerance limit: Set the allowable error limit, and automatically identify and alarm when exceeding the limit.

Data statistics: Calculate the mean, mean square error, maximum and minimum values to directly assess uncertainty.

Standard conversion: Test results can be converted into Brinell, Vickers, Knoop hardness, and tensile strength.

Curvature correction: Automatically corrects the measurement results of curved parts.

Test resolution: 0.1HR

Preload: 98.07N/10kgf

Main load: 588.4N/60kgf, 980.7N/100kgf, 1471N/150kgf

Load holding time: 2-50 seconds, adjustable

Maximum testing space: vertical 430mm (or 450mm), horizontal 200mm

Power supply: 220V/110V, 50Hz, 4A

Size: 730mm X 400mm X 1000mm

Weight: 160kg

Standard configuration:

|