1、 Introduction to Working Principle and Application Scope

Under the combined effect of the radiation heat generated by the cylindrical jacket heating of liquid materials in a vacuum state and the conduction and radiation heat generated by the heating of the load-bearing jacket plate of the conveying steel strip, the drying temperature and the running speed of the mesh belt are adjusted to quickly dry and dehydrate the materials from the feeding end to the discharging end to meet the process requirements. The dried materials are scraped off by a specialized discharging mechanism under the cleaning of the scraping mechanism, thus achieving the purpose of drying.

Widely used in industries such as medicine, food, chemical, and biotechnology for low-temperature dehydration and drying.

2、 Characteristics

1. The materials are evenly spread on the conveying drying plate under the action of the spray mechanism spray. Spread and dry evenly, with controllable thickness of the material layer.

2. Vacuum drying materials dry at relatively low temperatures and have less destructive properties.

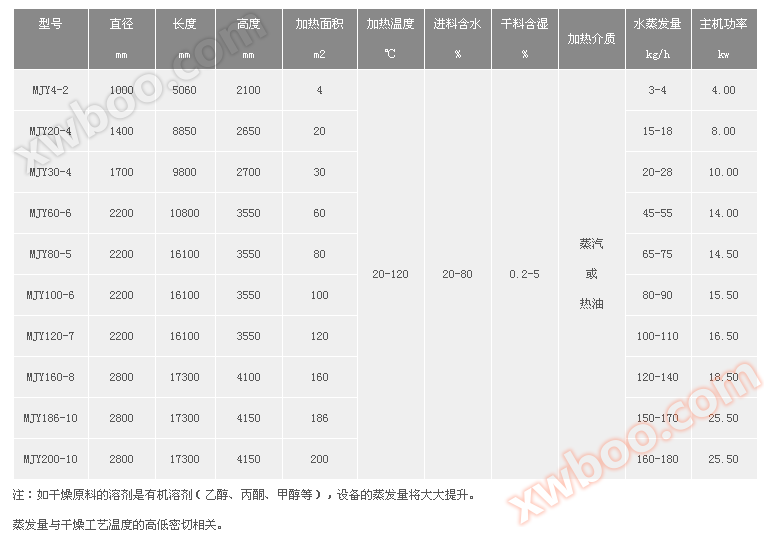

3、 Technical parameters (the values in the table below are for reference only during selection)

4、 Process flowchart