Excellent cost-effectiveness measuring machine, providing the widest applicability

The Inspector series coordinate measuring machine provides a universal inspection solution for modern manufacturing enterprises, realizing convenient, fast, and reliable geometric measurement. It can not only timely obtain product geometric dimensions and tolerance data, but also provide guarantees for high-quality product manufacturing; At the same time, it can also assist users in shortening the investment return cycle of the product and obtaining maximum returns.

The Inspector series measuring machine adopts the latest mechanical design technology and advanced material processes, providing excellent high precision and dynamic characteristics for the entire machine; This machine has multiple size series, with a travel range ranging from the smallest 400mm × 500mm × 400mm to 1000mm × 2100mm × 800mm, thus assisting different types of manufacturing enterprises in completing various industrial metrology applications, including first and final piece inspection, quality inspection, fixture verification, and process control tasks.

Technical Specifications

Inspector's travel range and dimensions

| model | Travel range (mm) | Dimensions (mm) |

| 04.05.04 | 400×490×390 | 1030×1160×2130 |

| 04.07.04 | 400×690×390 | 1030×1285×2340 |

| 05.07.05 | 500×700×500 | 999×1445×2562 |

| 07.10.05 | 700×1000×500 | 1199×1740×2562 |

| 07.10.07 | 700×1000×680 | 1199×1740×2915 |

| 06.08.06 | 600×800×680 | 1150×1623×2638 |

| 06.10.06 | 600×1000×600 | 1150×1823×2658 |

| 08.10.06 | 800×1000×600 | 1350×1823×2658 |

| 08.12.06 | 800×1200×600 | 1350×2023×2658 |

| 10.12.08 | 1000×1200×800 | 1600×2177×2936 |

| 10.15.08 | 1000×1500×800 | 1600×2477×2946 |

| 10.21.08 | 1000×2100×800 | 1600×3077×2946 |

According to customer requirements, we can provide sizes of 12.XX.10, 15.XX.10, and 15.XX.12 series.

Technical Features

Based on mature technology

The lightweight outer cover reduces the weight of the entire machine, thereby improving efficiency.

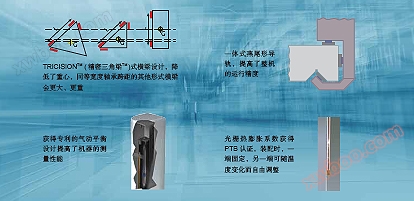

The patented X-directional "precision triangular beam" design enhances the rigidity to mass ratio of the entire machine, thereby improving measurement accuracy and operational stability.

The thick and stable granite workbench reduces the noise caused by vibration.

The dovetail guide rail is processed as a whole on a granite platform (this technology has been patented), which improves the accuracy and repeatability of the machine.

Remote placement of the motor reduces movement mass, improves speed, and avoids the impact of motor heating on machine performance.

The patented pneumatic balance design has improved the measurement performance of the machine.

Adopting advanced high-resolution gold grating ruler, its thermal expansion coefficient has obtained PTB certification.

The controller is fixed on one side of the host for easy overall movement.