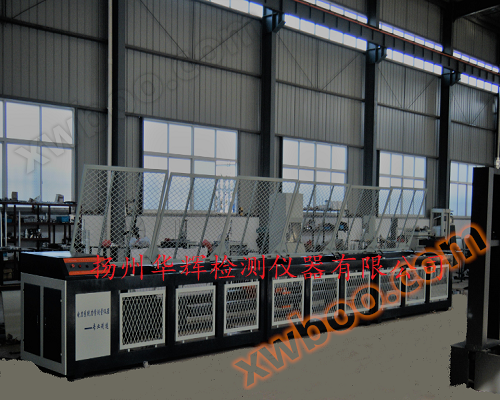

The specialized horizontal tensile testing machine for power fittings is mainly used for tensile performance testing of various metal components, steel cables, chains, anchor chains, lifting belts, separation discs, power attachments, wires and cables, double hooks, lifting ropes, steel wire ropes, hoisting ropes, chain hoists, wire tensioners and other flexible parts.

Features of HS series horizontal tensile testing machine for power fittings:

1. The device adopts a load sensor and a spherical centering device, and is composed of a thrust cylinder, a reverse frame, and other components to form a proximal tensile loading mechanism; The remote crossbeam is equipped with a walking drive and a small oil source, which can automatically move, automatically pin, and independently clamp, making it easy to adjust the test space. The equipment adopts a dedicated constant power hydraulic source drive, electro-hydraulic servo control technology, computer data acquisition and processing, and can achieve fully automatic closed-loop control. The equipment consists of a test host, an oil source system (hydraulic power source), a measurement and control system, an electrical system, etc

2. The servo cylinder is installed inside the cylinder seat and connected to the moving crossbeam through a load sensor. The test force reverse frame is composed of the moving crossbeam, cylinder, two pull rods, and front pull head seat. A movable rear pull head seat is installed in the force application frame, and the front and rear pull head seats are respectively connected to the sample. The test force is applied to the sample by driving the reaction frame through the cylinder. The position of the movable pull head seat can be adjusted step by step according to the specifications and length of the sample to adjust the stretching space. The sample is connected by a pin type connection, and the oil circuit adopts a flow control valve adaptive servo control test process. The high-precision load sensor measures the force, and the computer screen displays the test force and test curve. The test data is automatically processed according to the requirements of the test method.

3. A testing machine is a specialized high-precision testing equipment suitable for tensile and compressive testing of steel structure fittings, as well as tensile testing of various rod, bar, tube circular specimens, flat plate specimens, steel wire ropes, and other specimens. This device can achieve automated operation and has two testing spaces, namely compression testing space and tensile testing space. In the compression space, compression testing of welded balls and other specimens can be directly completed. Due to the equipped spherical special fixtures and pressure plates with spherical centering, it meets the national compression testing standards; Equipping hydraulic wedge-shaped jaws in the stretching space allows for direct tensile testing of circular specimens, finished components, steel strands, and other specimens. After replacing the fixtures, tensile testing of steel wire ropes can be conducted; The above experiments can be completed automatically through computer software operation.

4. The testing machine adopts a steel plate welded frame structure, segmented moving crossbeams to adjust the testing space, single output rod double acting piston cylinder to apply testing force, manual or servo control of the testing process, load sensor force measurement, microcomputer display of testing force and testing curve.

Technical parameters of the testing machine:

| Test force (KN) | 100 | 200 | 300 |

| Relative error of test force indication | ≤ ± 1% of the indicated value | ||

| Test force measurement range | 0.4%-100%FN | ||

| Stretch space (mm) | 1000, 5000, 10000, 30000 customized according to user requirements | ||

| Space adjustment method | Pin fixation, adjustment spacing 500mm or 800mm | ||

| Piston loading speed (mm/min) | 0-100 | ||

| Piston no-load speed (mm/min) | 200 | ||

| Piston stroke (mm) | 500, 1000, 1500, 2000 customized according to user requirements | ||

| Pre tensioning stroke (mm) | 500, 1000, 1500 customized according to user requirements | ||

| Round specimen tensile attachment (mm) | Φ13-Φ60 | Φ15-Φ70 | Φ15-Φ70 |

| Pin type stretching attachment | Customize according to user requirements | ||

| Casting attachments | Customize according to user requirements | ||

| The external dimensions of the host are approximately mm | According to the stretching space * 1300 * 900 | According to the stretching space * 1400 * 1050 | According to the stretching space * 1450 * 1100 |