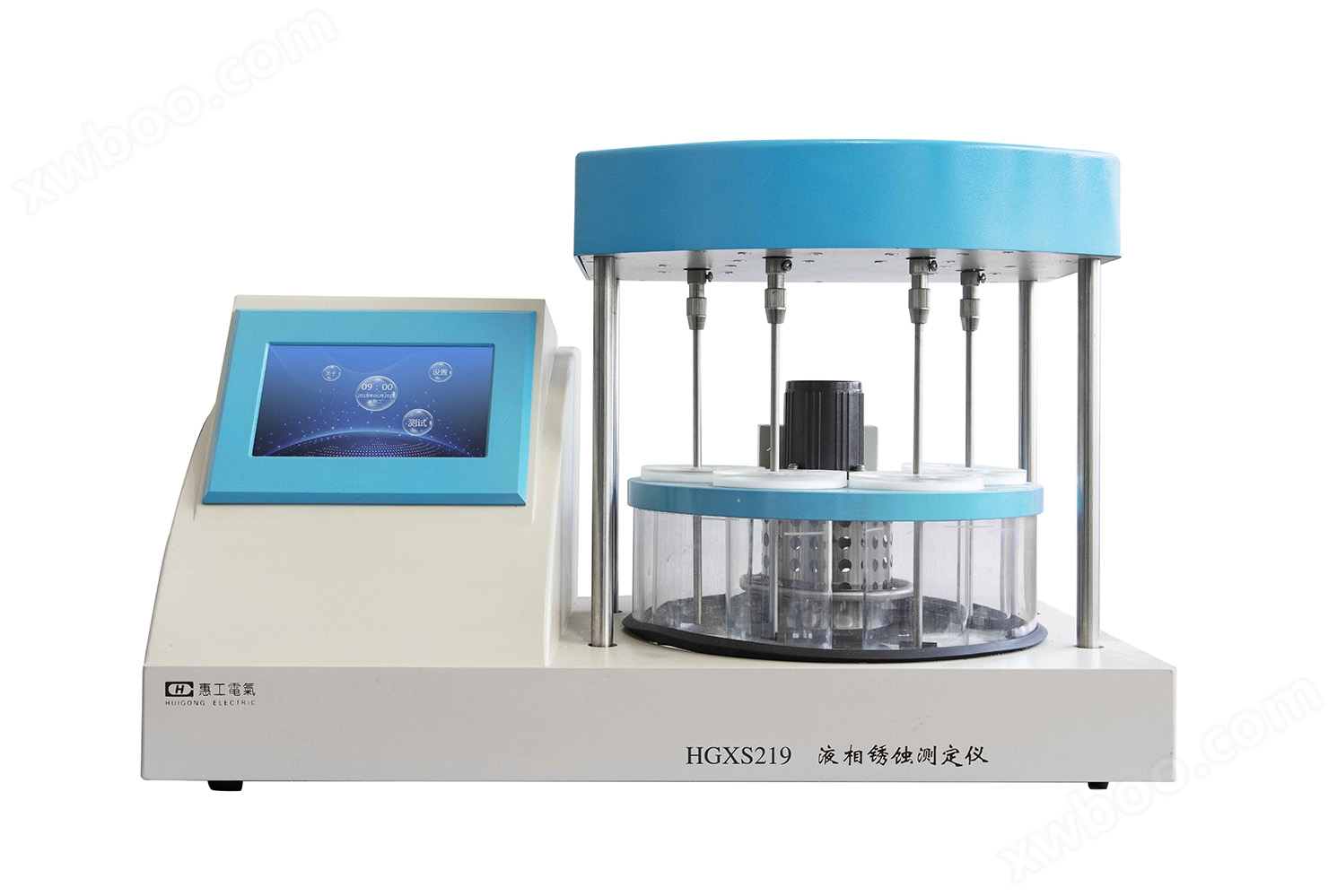

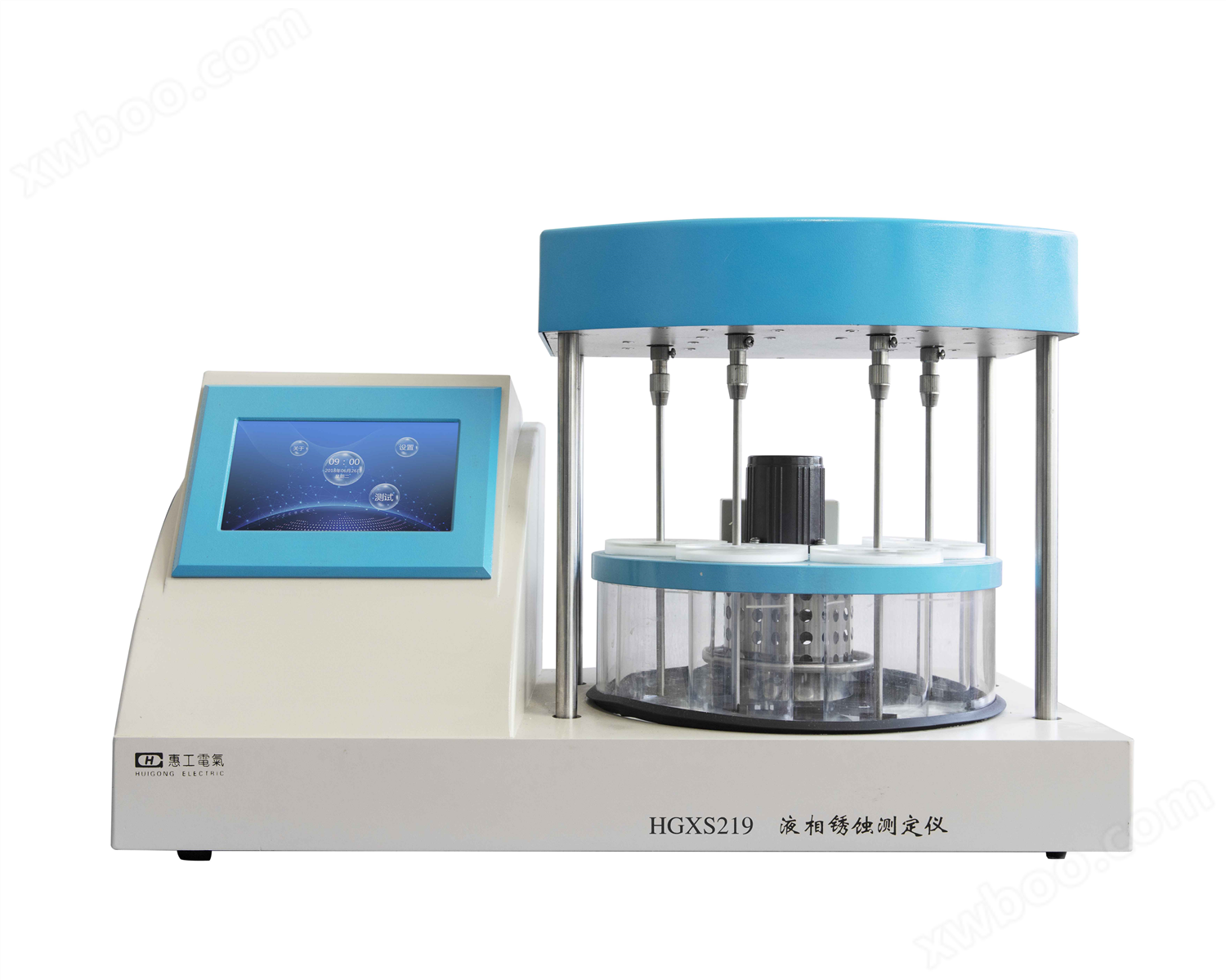

HGXS219typeThe liquid-phase corrosion tester is in accordance with national standardsGB/T 11143Design and manufacture. Mainly used for determining the rust prevention ability of metal parts when lubricating oil is mixed with water under standard experimental conditions, and evaluating the rust prevention ability of mineral oil and turbine oil with inhibitors on iron parts when mixed with water; The same applies to the determination of rust prevention ability of hydraulic oil and circulating oil. Widely used in departments such as power, petroleum, chemical, commercial inspection, and scientific research.

Main technical parameters

Applicable standards:GB/T 11143-2008

Temperature control range: room temperature~99℃

Temperature measurement resolution:±0.01℃

Temperature control accuracy:±0.1℃

Temperature control time:0~100Hours can be set arbitrarily

Number of test holes: Four holes (can be controlled separately)

Control method:1Standard method:According to the national standard;

2Customization method: Temperature, room temperature~99℃ can be set arbitrarily

Oil water mixing time:0~6000minute Set separately and arbitrarily

Mixing method: mixing paddle1000±20change/divide;Magnetic stirring 1000±20change/divide

environmentTemperature:5℃~40℃

environmentHumidity:≤85%(No condensation)

Power Supply:AC220V±10% 50Hz±5%

Power:1200W

shapesize:640×330×415mm

main features

■ true colorGUITouchscreen interface, intuitive display and easy operation

■ High temperature measurement and control accuracy, users can calibrate the temperature themselves

■ Water free anti dry burning protection, automatic shutdown for overheating and over heating, ensuring experimental safety

■ Each experimental hole is driven by an independent brushless motor, which can control the experimental process separately;Adopting a motor direct drive structure with low noise

■ There are two mixing methods to choose from: national standard mixing and magnetic mixing

■ Automatic control of the experimental process, with automatic prompt function, automatic alarm when the test time is up, users only need to observe the rusting situation of the experimental rod

■ Optimized instrument structure, bathtub easy to clean and replace

■ Equipped with remote communication function, can connect to the network, and upload and download experimental data (optional)

■ Equipped with permission management function, it can limit the scope of personnel using the instrument

■ Equipped with standard workflow and custom working modes, convenient for users to use