Product Introduction:

The HB-3000DI image digital Brinell hardness tester adopts closed-loop control electronic automatic loading load, with high force value accuracy and can be set by software;

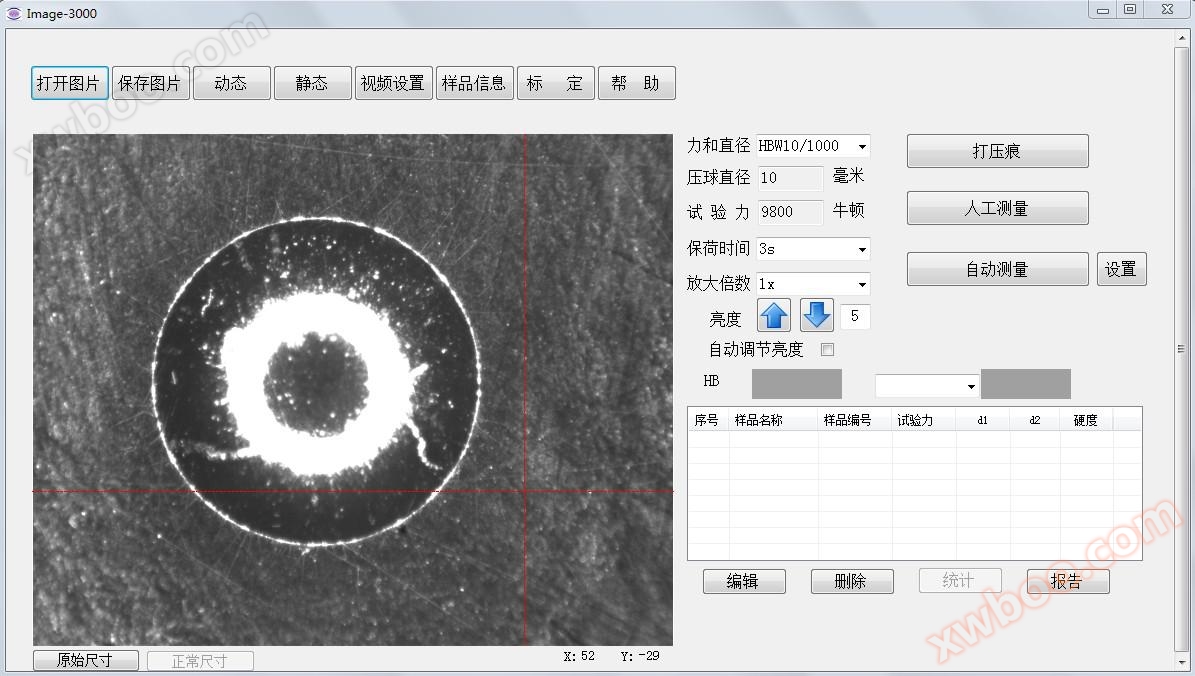

The hardness value is automatically measured by a computer through an image;

The hardness value can also be measured on the sample through a mobile digital display test eyepiece (20X) and printed.

Technical parameters:

Software:

1. Suitable for various loads of Brinell hardness tester;

2. Easy to install, can use a laptop instead of a desktop computer;

3. Clear image and accurate measurement;

4. Indentation measurement can be done manually or automatically;

5. Calibration is performed using a micrometer or hardness block, which can be automatically calibrated;

6. Convert hardness to other hardness according to national standards and ASTM;

7. Hardness value statistics and hardness exceeding alarm;

8. The interface is simple, the operation is easy, and there is no need for training to use it;

9. Test report, automatically generated and customizable by users, including sample information, hardness data, statistics, and indentation images.

Standard configuration:

|

name |

quantity |

name |

quantity |

|

Brinell hardness tester mainframe |

1 unit |

Diameter 2.5, 5, 10mm hard alloy ball indenter |

1 each |

|

standard hardness block |

3 pieces |

Mobile digital display test eyepiece -20x |

1 piece |

|

Camera -1.3 million pixels |

1 piece |

optical interface |

1 piece |

|

power line |

1 piece |

Software CD |

1 sheet |

|

Large, medium, and V-shaped test benches |

1 each |

Product user manual, product qualification certificate |

1 copy each |