Product Description

German Fischer DualScope FMP40+Probe FD10 dual function integrated coating thickness gauge----Measure the thickness of each layer in the coating system (double coating) of galvanized and repainted steelFMP40The type of instrument is better than the basic modelFMP10andFMP20The instrument has more functions. For example, large memory that can store more applications, a large amount of graphics, and statistical computing functions. This can be applied to a wider range of applications and meet higher customer requirements. The free input of upper and lower limit tolerances can help customers conduct more comprehensive analysis and statistics of the production process. More measurement methods are available to choose from, helping you achieve perfect measurements.

FMP40 function (additional features compared to FMP20)):

◇ Automatic recognition of substrate (FMP40)

◇Can be stored100An application that includes calibration information.

◇Can be stored20,000A reading,Storage4,000A data set.

◇The data set contains date and time information,Can be manually operatedCorrect the stored readings.

◇Multiple applications can use the same normalization/Calibration information.

◇canThe application name can be edited through a computer

◇haveData group statistics and data statistics,Being able to showcaseHistogram display of measurement data.

◇Can input upper and lower limit tolerances and estimate themcpandcpkvalue

◇When the measurement result exceeds the tolerance range, the instrument emits visual and audible warnings.

DUALSCOPE FMP40 coating thickness gauge is a user-friendly device for measuring coating thickness and flexible data acquisition. The DUALSCOPE FMP40 film thickness gauge has a storage capacity of up to 10000 measurement data for 1000 data sets, with dynamic storage allocation capability. 100 measurement applications' memory can be used to store calibration and related measurement data.DUALSCOPE FMP40 paint film thickness gaugeUsing Fischer's intelligent measuring probe ED10, MP40 will automatically detect the material of the substrate and apply appropriate testing methods: eddy current method or electromagnetic induction method. Can automatically identify different probes. Application specific calibration parameters are stored in the measuring probe, so the instrument can immediately perform measurements once any probe is connected.DUALSCOPE FMP40 thickness gaugeAdopting eddy current method according to DIN EN ISO 2360, ASTM B244 standards and electromagnetic induction method according to DIN EN ISO 2178, ASTM B499 standards.

Application storage

※ Can store 100 applications including calibration lettersinterest

Simulated display

※Matrix measurement mode can be used for a large number of measurements

※Strange value control: The instrument can automatically eliminate erroneous measurement values

|

FMP 20 probe selection: |

|

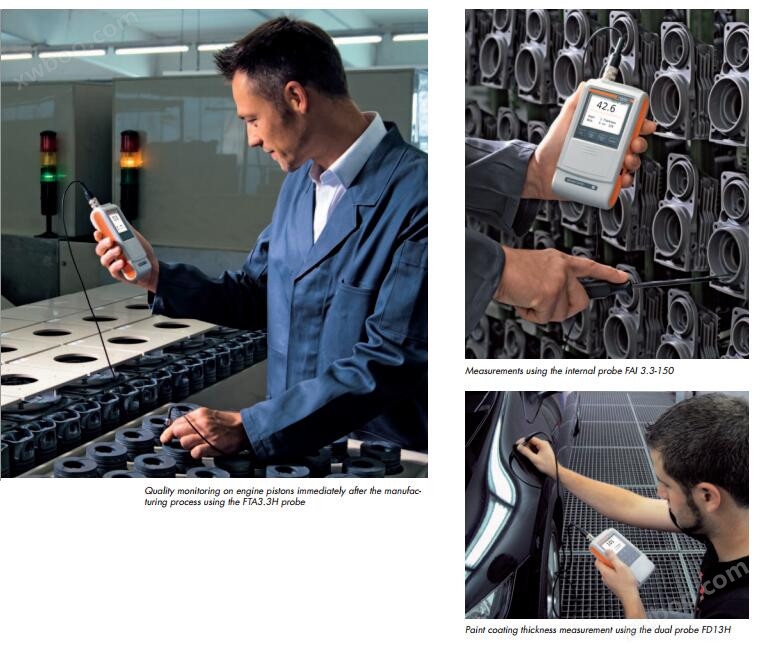

The quality of a measurement is mainly determined by several key factors. Including: selecting appropriate probes and the quality of the probes themselves. Helmut Fischer GmbH provides you with a wide range of high-precision probes of excellent quality, all of which are independently developed and produced according to high-quality requirements. The type of coating/substrate is an important criterion for selecting probes. In addition, the approximate thickness of the coating, the material of the substrate, the area of the measurement point, and the shape and surface condition of the sample are all factors that need to be considered when selecting a probe. Curvature compensation probe (eddy current method) is suitable for samples with different curved surfaces; The dual contact probe can achieve precise results on rough surfaces. FMP1, FMP20, FMP30, and FMP40 instruments can all meet your different measurement needs by connecting different probes.

Magnetic induction probe FGAB1.3 604-141The probe is suitable for measuring the thickness of electroplating, coatings, and paint layers, with a measurement range of 0-2000 μ m FGABI1.3-150 604-175The probe is suitable for holes, pipes, and fine grooves, with a diameter of ≥ 9 mm and a measurement range of 0-1600 μ m FGA2H 604-174Suitable for thickness measurement of electroplating, coatings, and paint layers. Due to its large size, the probe is also suitable for workpieces with relatively rough surfaces. Measurement range 0-1500 μ m V7FKB4 604-180The dual contact probe can achieve good repeatability on rough surfaces. Its reliable placement and constant pressure are also suitable for soft coating. Measurement range 0-2000 μ m

FKB10 604-177 dual contact right angle probe is particularly suitable for measuring thick coatings. It exhibits better repeatability accuracy on rough surfaces than single contact probes, with a measurement range of 0-8 mm

Eddy current probe

FTA3.3H 604-142 is suitable for thickness measurement of coatings, paints, and plastic layers on non ferromagnetic substrates, with a measurement range of 0-1200 μ m

FTD3.3 604-189 is suitable for measuring the coating thickness of flat samples, holes, pipes, and transition areas, with a measurement range of 0-1200 μ m

FTD3.3 604-189 is highly suitable for measuring the thickness of coatings, paints, anodizing, and plastic layers on curved non ferromagnetic workpieces due to its use of curvature compensation technology. Measurement range 0-800 μ m

Dual mode/dual-purpose probe

FD10 604-143 adopts a dual-mode design of magnetic induction method and eddy current method. It can automatically switch to the corresponding measurement principle for operation. Measurement range NF/Fe0-1300 μ m, Iso/NF0-800 μm

The FDX10 604-246 dual-purpose probe can simultaneously measure the thickness of two types of coatings (paint layer and zinc layer) on iron or steel. The thickness of hot-dip galvanizing in the transition layer can also be measured (Zn ≥ 70 μ m). Measurement range 0-800 μ m

For the selection of probes, we recommend that you choose the probe that is suitable for your application. You can request a sample of "Probes and Accessories" to learn more about probes.

|