1、 Overview of drum dryer

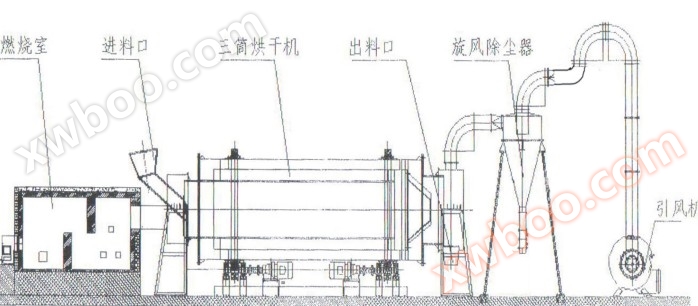

Drum dryers are widely used in industries such as building materials, metallurgy, mineral processing, chemical engineering, and cement. They are mainly used for materials with high humidity and weight, such as slag, limestone, clay, river sand, quartz sand, and water slag. The slag drying production line mainly consists of a rotary cylinder, induced draft equipment, high-speed dispersing equipment, lifting plate, self-cleaning device, transmission device, conveying equipment, hot air equipment, reducer, support device, and sealing device. The complete set of drying equipment has the advantages of reasonable design, excellent production, stable performance, advanced technology, high output, low energy consumption, small footprint, and high degree of mechanization.

2、 Application scope of drum dryer

A drum dryer is a type of dryer that processes large amounts of materials. Due to its reliable operation, high operational flexibility, strong adaptability, and large processing capacity, it is widely used in metallurgy, building materials, food, light industry, chemical industry, coal, pharmaceutical and mining industries. Rotary drum dryers are generally suitable for granular materials and can also be used to dry sticky paste like materials or materials with high moisture content by partially adding materials. His advantages are high production capacity, wide applicability, low flow resistance, large allowable fluctuation range in operation, and convenient operation. Slag dryer and drum dryer are commonly used for drying sand, mineral powder, coal slurry, chicken manure, cow manure, etc.

3、 Working principle of drum dryer

Dry and wet materials are transported to the hopper by a belt conveyor or bucket elevator, and then enter the feeding end through the feeding pipeline through the feeding machine of the hopper. The slope of the feeding pipeline should be greater than the natural inclination angle of the material, so that the material can flow smoothly into the dryer. The dryer cylinder is a rotating cylinder slightly inclined from the horizontal line. The material is added from the higher end, and the heat carrier enters from the lower end, coming into counter current contact with the material. There are also cases where the heat carrier and the material flow together into the cylinder. As the cylinder rotates, the material moves to the lower end under the action of gravity. During the forward movement of the wet material inside the cylinder, it directly or indirectly receives heat from the heat carrier, allowing the wet material to dry, and then is sent out through a belt conveyor or screw conveyor at the discharge end.

There is a copying plate installed on the inner wall of the drum dryer body, which is used to pick up and sprinkle the material, increase the contact surface between the material and the airflow, improve the drying rate, and promote the material to move forward. Thermal carriers are generally divided into hot air, flue gas, etc. After passing through the dryer, the heat carrier generally needs a cyclone dust collector to capture the materials carried in the gas. If further reduction of exhaust dust content is required, it should be discharged after passing through a bag filter or wet dust collector.

4、 Characteristics of drum dryer

1. Drum dryer has strong overload resistance, large processing capacity, low fuel consumption, and low drying cost;

2. The drum dryer adopts a downstream drying method, where hot air and wet materials enter the dryer from the same side. High temperature air can be used to achieve high evaporation intensity, and the outlet temperature of the dryer is low, resulting in high thermal efficiency;

3. The drum dryer can change its operating parameters according to the properties of different materials, so that the materials can form a stable fully broken fabric curtain inside the dryer cylinder, and the mass and heat exchange is more sufficient;

4. The drum dryer adopts a new type of feeding and discharging device, which eliminates the phenomena of feeding blockage, discontinuity, unevenness, and return of materials in the vertical dryer, and reduces the load of the dust removal system;

5. The drum dryer achieves "zero horizontal thrust", greatly reducing the wear of the retaining wheel and ensuring smooth and reliable operation of the drum body;

6. The drum dryer adopts a "self-aligning supporting wheel device", which ensures that the matching between the supporting wheel and the rolling ring is always in linear contact, greatly reducing wear and power loss;

7. The drum dryer can control the moisture content of the product according to user requirements.

Rotary Dryer

Drying equipment used for drying grains, China is a major grain producing country with a high demand for drying machines. It is becoming increasingly important to increase investment in grain dryers and increase the construction of grain dryer facilities. The automation, economy, and reliability of dryers are crucial for future grain production.

Introduction to drum dryer

Drum dryer is one of the traditional drying equipment, with reliable operation, high flexibility, strong adaptability, and large processing capacity. It is widely used in metallurgy, building materials, chemical industry, coal washing, fertilizer, ore, sand, clay, kaolin, sugar and other fields. The diameter is from Φ 1000 to Φ 4000, and the length is determined according to the drying requirements. At the center of the drum dryer, it is possible to avoid adding a dispersing mechanism. Wet materials entering the drying cylinder are repeatedly picked up and thrown off by the scraper on the drum wall. During the falling process, they are broken into small particles by the dispersing device, greatly increasing the specific area and fully contacting and drying with hot air.

Characteristics of drum dryer

The drum dryer has a large processing capacity, low fuel consumption, and low drying cost. Drying machines have the characteristic of high temperature resistance and can use high-temperature hot air to quickly dry materials. Strong scalability, designed with production margin in mind, even if the output increases slightly, there is no need to replace equipment. The equipment adopts a self-aligning tugboat structure, and the cooperation between the tugboat and the rolling ring is good, greatly reducing wear and power consumption. The specially designed gear wheel structure greatly reduces the horizontal thrust caused by the tilting operation of the equipment. Strong overload resistance, smooth operation of the cylinder, and high reliability.

Working principle of drum dryer

The drum dryer is mainly composed of rotating body, lifting plate, transmission device, support device, sealing ring and other components. Dry and wet materials are transported to the hopper by a belt conveyor or bucket elevator, and then enter the feeding end through the feeding pipeline through the feeding machine of the hopper. The slope of the feeding pipeline should be greater than the natural inclination angle of the material, so that the material can flow smoothly into the dryer. The dryer cylinder is a rotating cylinder slightly inclined from the horizontal line. The material is added from the higher end, and the heat carrier enters from the lower end, coming into counter current contact with the material. There are also cases where the heat carrier and the material flow together into the cylinder. As the cylinder rotates, the material moves to the lower end under the action of gravity. During the forward movement of the wet material inside the cylinder, it directly or indirectly receives heat from the heat carrier, allowing the wet material to dry, and then is sent out through a belt conveyor or screw conveyor at the discharge end.

Drum dryer

The drum dryer has the advantages of reasonable structure, excellent production, high output, low energy consumption, and convenient operation. Drum dryer is widely used in building materials, metallurgy, chemical industry, cement industry for drying materials such as slag limestone, coal powder, slag, clay, etc.

Product details: The drum dryer has the advantages of reasonable structure, excellent production, high output, low energy consumption, and convenient operation. Drum dryer is widely used in building materials, metallurgy, chemical industry, cement industry for drying materials such as slag limestone, coal powder, slag, clay, etc. The drum dryer can also be used for the production of compound fertilizers, drying fertilizers with certain humidity and particle size. It can also be used for drying other materials. The distribution and angle design of the lifting plate of this machine are reasonable, and its performance is reliable. Therefore, it has high thermal energy utilization rate, uniform drying, fewer cleaning times for materials, and is suitable for easy maintenance.

Structure of drum dryer

The drum dryer is mainly composed of rotating body, lifting plate, transmission device, support device, sealing ring and other components. The main body of the drum dryer is a rotating cylinder that is slightly inclined from the horizontal line. The cylinder is driven by gears, with a speed of generally 2-6r/min. The inclination of the cylinder is related to its length, usually between 1 ° and 5 °. The material is fed into the higher section of the rotary drum and comes into contact with hot air. As the cylinder rotates, the material flows towards the lower end under the action of gravity and is dried before being discharged. Due to the negative pressure condition of the dryer, sealing devices are used at both the feeding and discharging ends to prevent air leakage.

The drum dryer adopts an advanced drum and plate structure. After the material enters the cylinder, it is continuously scattered in the hot air flow under the action of the plate, so that the surface of the particles is fully in contact with the hot air, thereby achieving the best drying effect and completing the drying process of the material.

Working principle of drum dryer equipment

Dry and wet materials are transported to the hopper by a belt conveyor or bucket elevator, and then enter the feeding end through the feeding pipeline through the feeding machine of the hopper. The slope of the feeding pipeline should be greater than the natural inclination angle of the material, so that the material can flow smoothly into the dryer. The dryer cylinder is a rotating cylinder slightly inclined from the horizontal line. The material is added from the higher end, and the heat carrier enters from the lower end, coming into counter current contact with the material. There are also cases where the heat carrier and the material flow together into the cylinder. As the cylinder rotates, the material moves to the lower end under the action of gravity. During the forward movement of the wet material inside the cylinder, it directly or indirectly receives heat from the heat carrier, allowing the wet material to dry, and then is sent out through a belt conveyor or spiral classifier at the discharge end.

Characteristics of drum dryer

The distribution and angle design of the lifting plate of this machine are reasonable, and its performance is reliable. Therefore, it has the characteristics of high heat energy utilization rate, uniform drying, few material cleaning times, and convenient maintenance.

The two devices adopt a self-aligning tugboat structure, with good coordination between the tugboat and the rolling ring, greatly reducing wear and power consumption.

The specially designed stop wheel structure in this device greatly reduces the horizontal thrust caused by the tilting operation of the equipment. Strong overload resistance, smooth operation of the cylinder, and high reliability.

The drying machine has the characteristic of high temperature resistance and can use high-temperature hot air to quickly dry materials. Strong scalability, designed with production margin in mind, even if the output increases slightly, there is no need to replace equipment.

The 5-drum dryer has a large processing capacity, low fuel consumption, and low drying cost.

Drum dryer

Drying equipment used for drying grains, China is a major grain producing country with a high demand for drying machines. It is becoming increasingly important to increase investment in grain dryers and increase the construction of grain dryer facilities. The automation, economy, and reliability of dryers are crucial

1. Introduction to drum dryer

Drum dryer is a common drying equipment in dryers, with a wide operating range, strong practicality, and a large processing range. It is currently a popular drying equipment among users. The diameter of ordinary drum dryers ranges from Φ 1000 to Φ 4000, and can also be customized according to current user requirements. This equipment is mainly used in metallurgy, building materials, chemical industry, coal washing, fertilizer, ore, sand, clay, kaolin and other fields, and is also a leader in the drying industry in our country.

2. Scope of application of drum dryer

1) Chemical, mining, metallurgical and other industries, such as ore, slag, coal, metal powder, clay, diatomaceous earth, kaolin.

2) Agriculture, feed, and fertilizer industries, such as straw, grass, leaves, fish meal, corn sauce, starch residue, distiller's grains, medicine residue, fruit residue, soy sauce residue, sugarcane bagasse, peat, organic compound fertilizer, sludge, aquatic product waste, food factory waste, slaughterhouse waste, organic fertilizer, inorganic fertilizer, phosphate fertilizer, and ammonium sulfate.

3) Dry powdered and granular materials with special requirements. Such as various crystals, light calcium carbonate, activated clay, magnetic powder, graphite, inorganic mud, clay, lime slurry, ore slurry, phosphorus slag, and aluminum plant red mud.

4) Materials that require low-temperature drying and require continuous drying in large quantities.

3. Structure of drum dryer

The drum dryer is similar to other drying mechanisms, mainly composed of a rotating body, a lifting plate, a transmission device, a support device, and a sealing ring. A dryer is a cylinder that is slightly inclined from the horizontal direction. Materials are added from the higher end, and high-temperature flue gas flows into the cylinder together with the materials. As the cylinder rotates, the materials move to the lower end due to gravity. A copying plate is installed on the inner wall of the cylinder to pick up and sprinkle the material, increasing the contact surface between the material and the airflow to improve the drying rate and promote the material to move forward. The dried product is collected from the bottom and lower part.

4. Characteristics of drum dryer

1) Fast processing speed, large processing capacity, and low fuel consumption.

2) Low cost, safe to use, and equipped with certain protective measures.

3) In terms of exterior design, it adopts a combination of tugboats and rolling rings to make it more sturdy.

4) The specially designed gear wheel structure greatly reduces the horizontal thrust caused by the tilting operation of the equipment. Strong overload resistance, smooth operation of the cylinder, and high reliability.