Welcome to personalized customization

A professional customization team can provide personalized customization services according to the needs of customers. If you have such needs, please feel free to consult the customer service hotline: 13751030658.

Welcome to free sampling

Yunteng Laser can provide free sampling services. For technical consultation, process consultation, product consultation, and transportation consultation, please call directly!

Welcome to visit in person

Yunteng Laser's product quality is industry-leading. Welcome to visit and inspect the company on site! Multiple companies designated laser brands and witnessed together.

Application features:

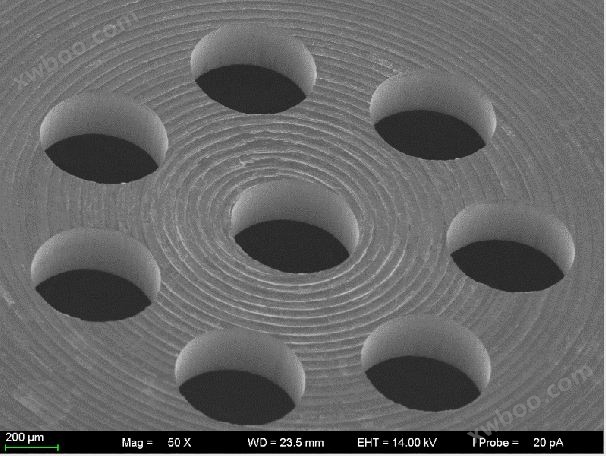

This equipment is mainly used for ceramic drilling, slicing, and cutting, suitable for various oxide ceramics, diluted ceramics, including ceramic materials such as alumina, zirconia, glass oxide, silicon nitride, silicon carbide, aluminum nitride, etc. It can also be used for cutting and slicing various types of silicon wafers.

Localized irradiation is applied to the surface of ceramic substrates or metal sheets to rapidly vaporize and peel off the material in a very short period of time, thereby achieving the purpose of cutting and drilling.

The main characteristics of ceramic laser cutting are as follows:

1. Good cutting quality due to the small laser spot, high energy density, and fast cutting speed.

2. Cutting with narrow gaps, laser cutting typically has a cutting gap of 0.10-0.20mm to save material.

3. The perpendicularity of the cutting edge is good, the cutting surface is smooth without burrs, and the surface roughness is generally controlled at Ra: 12.5 or above.

4. Small heat affected zone: Laser processing has fine cutting seams, fast speed, and concentrated energy, so the heat transferred to the cut material is small, causing very little deformation of the material. In some cases, the width of the heat affected zone is below 0.05mm.

Machine parameters:

| power | 10W/15W |

| Beam Quality | M2 <1 1 |

| Laser output power | 0%~100% continuously adjustable |

| laser output frequency | 5KHz~80KHz continuously adjustable |

| Power stability (8h) | <±1%rms |

| Focusing spot diameter | <0.01mm |

| Tag type | Dynamic tagging/static tagging |

| Marking speed | 800 standard characters |

| Minimum line width | ≤0.005mm |

| Minimum character | 0.15mm |

| repeatability | ±0.003mm |

| laser device | imported with original packaging |

| System operating environment | WindowsXP/2000/98 |

| Cooling method | forced air cooling |

| Ambient temperature | 15℃~35℃ |

| Power demand | 220V/single-phase/50Hz/<800W |

| Laser module lifespan | 30000 hours |

Shenzhen Inte Laser Technology Co., Ltd. is a professional manufacturer of automated high-precision laser application equipment; It is a high-tech enterprise that integrates research and development, production, sales, and after-sales service; At present, there are multiple invention patents, utility model patents, and computer software copyrights.

Inte Laser firmly believes that quality is the foundation of development. With advanced assembly technology, over 90% of imported raw materials, high-precision testing instruments and equipment, and strict and rigorous inspection standards, Inte Laser guarantees equipment quality and provides customers with automated, high-precision, high-efficiency, high index, and high stability products. Inte Laser adheres to the principle of technology first and constantly pursues technological innovation. More than 90% of its R&D team is composed of industry senior engineers, senior experts, master's degree holders, etc., specializing in the research and development of equipment for automated high-precision laser cutting, micro welding, drilling, marking, etching, resistance adjustment, and marking.

Inte Laser's independently developed and produced fully automatic wafer laser marking equipment, picosecond laser glass drilling equipment, high-precision glass/sapphire/filter laser cutting equipment, full screen laser precision cutting equipment, fully automatic SD card laser cutting, PCB/FPC laser marking equipment, fully automatic laser cutting surface mounting equipment, LCP laser precision cutting equipment, etc. have received high praise from many well-known enterprises.

Inte Laser has a comprehensive market and technical support system, with professional sales and after-sales outlets established in East and South China to ensure customers' satisfactory use of Inte Laser products.