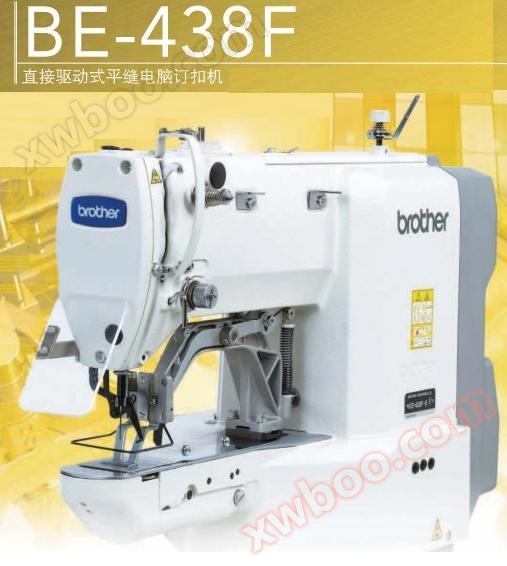

- model:KE-438F

- Brand:Brother card

- Type:Computer nail fastening machine

- Needle count:1

- Number of lines:1

- Number of aircraft heads:1

- Drive form:direct drive

- Target audience:For sewing, women's underwear and other nail fasteners

- Thread type:Flat seam

- Applicable locations:Used for nail buckles in clothing factories, underwear and bra factories

- External dimensions:

- Whole machine weight:

Direct driver computer nail buckle

Oil-free needle rod type

The trouble of not letting sewn clothes be contaminated by oil stains

Direct drive energy-saving, high-speed and accurate sewing

High speed sewing with beautiful stitching, achieving fast cycle time

Due to its direct drive flat seam computerized knotting machine, its high sewing quality and production efficiency greatly increase profits.

The rigidity of the sewing machine has been improved, and the servo controlled feeding device is used to sew completely according to the sewing data, greatly improving the sewing quality.

The lifting foot device is driven by a pulse motor, and the lifting foot height can be set through the operation panel, making the operation very easy.

Adopting a new type of motor, it has low power consumption and is economical and practical.

Low noise and low vibration, good working environment, and less likely to cause operator fatigue. Fast cycle time and overwhelming advantage in production efficiency. The speed reaches 3200rpm. Due to the ease of setting the presser foot height, the complete set of sewing operations has progressed rapidly.

The positioning of the sewing material is easy, greatly reducing the setting time, and the height of the lifting foot is set to 2 stages. The operating time has been reduced by about 27% (compared to our company). The preparation time can also be reduced, thereby shortening the entire cycle time.

Even with high-speed sewing, it can ensure accurate needle drop without distortion, and operate completely according to the sewing data, resulting in beautiful stitching.

The feeding device adopts primary servo control, and due to its high rigidity, it greatly improves the sewing accuracy.

It has a wide range of sewing performance and achieves low tension sewing.

The amount of excess wire at the end of the line has been reduced to 2-2.5mm, and no further processing is required.

Use oil-free needle bar for clean sewing. Adopting a 550W motor greatly enhances the needle penetration force. The minimum resolution is 0.05mm/1 pulse.

Easy to operate sewing machine

No tools are needed to set the presser foot height by entering numerical values on the control panel. We use a CF card that is operated by the control panel and has extremely simple data addition.

Low power consumption, economical and practical

Due to the use of a new direct drive motor, this computerized sewing machine is one of the lower energy consuming sewing machines on the market.

Comfortable working environment

Balanced design was adopted in the construction to reduce noise and vibration.

The sewing speed of 438F is 2700rpm.