Process flow of banana taro starch processing: The banana taro starch production line of Sida Company adopts a wet processing technology for starch production, without adding any additives. The entire process is technically mature, scientifically configured, and has a reasonable process.

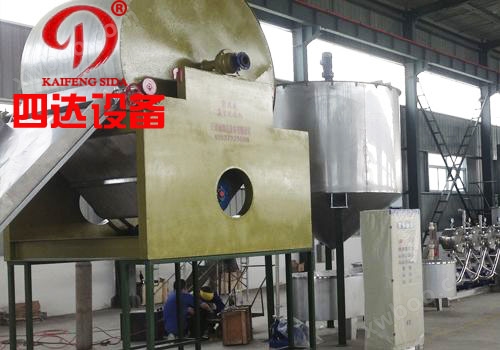

Banana and taro starch equipment

The production process of banana and taro starch is designed in nine stages: cleaning, stone removal, transportation, crushing, crushing, screening, sand removal, concentration and refining, dehydration, and low-temperature drying. The crushing and screening section adopts a bidirectional process of crushing and fine crushing. Through crushing, starch is released, and the powder yield is high. The multi-stage crushing and multi-stage filtration process is repeated in sequence. The crushed and filtered Ge residue is in the form of silk, with the advantages of low energy consumption, high starch extraction rate, and good starch quality, which improves the production efficiency and starch extraction rate of the production line.

Applicable objects and characteristics of banana and taro starch processing equipment:

The small-scale banana and taro starch equipment adopts the sedimentation tank method, which has the advantages of low investment, low automation, high manpower, high waste, and is greatly affected by weather factors, resulting in low yield. (Family workshop, soil processing factory)

The automated banana taro starch equipment is suitable for starch processing manufacturers and customers who use banana taro as raw material. The process runs automatically from the entire process of raw material cleaning, crushing, starch extraction, fine filtration, sand removal, concentration, refining, dehydration, drying, etc. The equipment has a high degree of automation.

The difference between standard kudzu starch processing equipment and economic type is that: 1. In terms of equipment configuration: the standard type is better than the economic type, with higher equipment configuration. The concentration and refining section adopts an 18 stage cyclone, resulting in higher starch extraction quality; 2. In terms of equipment materials: Standard equipment configurations often use stainless steel materials, which provide stronger equipment safety; 3. In terms of processing capability, the standard type has stronger processing capability than the economic type and is suitable for standardized starch production and manufacturing enterprises.

The main components of the banana and taro starch mechanical equipment include: screw conveyor, cage cleaning machine, filing and grinding machine, centrifugal screening unit, sand remover, washing cyclone, vacuum dewatering machine, airflow dryer, etc.

Process flow of banana taro starch mechanical equipment: banana taro - hydraulic conveying - cleaning and conveying - secondary cleaning - crushing - separation - sand removal - refining - airflow drying - finished product packaging.

Equipment process for processing banana and taro starch

Main indicators:

Requirements for raw materials of banana taro: fresh, free from mold and rot, and free from large amounts of sediment;

Water supply requirements: turbidity<0.1, hardness<100, SO2<0.55ppm, Iron<0.9 ppm;

No floating objects, pressure>0.2Mpa; Water consumption: 2-3 tons of water per ton of fresh kudzu

Auxiliary facilities

Transformers and distribution cabinets, water supply systems, corresponding warehouses and storage areas, micro powder collection tanks, transfer tanks, etc

For detailed parameters and configurations, please consult the Engineering Technology Department.

3D drawing of banana and taro starch processing equipment

Processing capacity of banana and taro starch processing equipment:

Equipment for processing about 5 tons of banana starch per hour, about 10 tons of banana starch per hour, about 20 tons of sweet potato starch per hour, about 30 tons of sweet potato starch per hour, about 50 tons of sweet potato starch per hour, and about 100 tons of sweet potato starch per hour

Friends who need to know about sweet potato starch processing equipment, potato starch processing equipment, cassava starch processing equipment, kudzu root starch processing equipment, and banana taro starch processing equipment can contact our technical team for 24-hour consultation. Manager Zhang (mobile number is WeChat)