1、 Preface:

The BGA rework station mainly consists of three independent temperature control zonesThe entire heating process can be roughly divided into: preheating stage---Insulation section - Heating section - Welding section 1- Welding section 2- Cooling section - Completing the entire heating process, essentiallyIt is to control the temperature rise and constant temperature. Due to the physical characteristics and welding needs of the circuit board, it is also necessary to control the slope of temperature rise. The temperature should rise to the set value according to the preset slope, and not exceed the allowable range of overshoot. If there is an overshoot beyond the allowable range, it may cause damage to the electronic components of the circuit board. Therefore, the entire process is not allowed to exceed the allowable range of overshoot. The constant value control of PLC is usually implemented using PID algorithm, but traditional PID algorithm requires parameter tuning, and to achieve no overshoot, PID parameters need to be repeatedly tuned, which has high requirements for debugging personnel. By using Gu Mei's touch screen all-in-one machine as a controller with dedicated control algorithms, it is possible to achieve a boost process without overshoot, with fewer parameters and simple adjustment, making it convenient to use.

IIBGA rework table description

The BGA rework station uses a Gu Mei integrated machine as the controller, which heats the upper and lower temperature zones and the IR preheating zone separately. The heat is blown to the temperature zone by a fan through the resistance wire. The fan runs continuously during the heating process, and the all-in-one machine heats up by conducting resistance wires through PWM cycles. Three K-type thermocouples provide feedback on the actual temperature situation, and the Gu Mei all-in-one machine adjusts the PWM duty cycle to control the temperature rise and fall based on the feedback actual temperature. Controlling the slope of temperature rise is also a difficult and critical point for BGA rework stations.

The upper and lower temperature zones are heated by hot air,The IR preheating zone (350 * 260) is equipped with infrared heating, with precise temperature control within plus or minus 3 ℃. Both upper and lower temperature zones can be set with 8-stage heating and 8-stage constant temperature control, and can store 50 sets of temperature curves, which can be called up at any time according to different BGA. BGA chips can be locally heated with hot air, and at the same time, a large-area infrared heater can be used to heat the bottom of the PCB board, which can completely avoid deformation of the PCB board during maintenance. By selecting, the upper and lower temperature zones can be used separately, and the energy of the upper and lower heating elements can be freely combined.

The IR preheating zone can adjust the output power according to actual requirements, which can evenly heat the PCB board without deformation. The external temperature measurement interface enables precise temperature detection, and can analyze and calibrate the actual collected BGA temperature curve at any time.

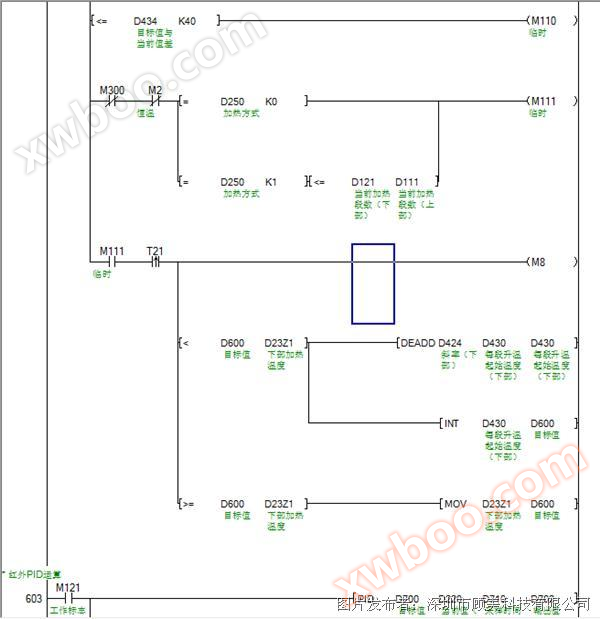

IIIsolution

useUsing a K-type thermocouple as feedback, the BGA rework station forms a closed loop to control the output duty cycle and draw a block diagram.

Adjust the response speed to the fastest and then increase it according to the slopeSV target value, in order to achieve heating according to the set slope.

Slope processing:

4Gu MeiTouch screen all-in-one machine controlcurve:

The temperature curve of the Gu Mei touch screen all-in-one machine conforms toControl indicators of BGA rework table,Realized a rising curve without overshoot.

Fiveoperating interfaceAnd program

six.BGAThe repair stationGeneral usage process:

Enter the debugging interface, edit a set of heating parameters, set the temperature for upper and lower heating, rise slope, constant temperature time, set the temperature for infrared heating, and some auxiliary functions such as advance buzzing time, buzzing time, and cooling time. After setting the parameters, click save to access and start heating. The debugging interface is used to set parameters, which are stored and can be directly retrieved for use the next time they are needed. Therefore, after debugging, there is usually no need to enter the debugging interface, just enter the operation interface and select the parameter group that needs to be heated.

For example:

(1)Preheating section (one section)0: After the machine program is started, the upper heating enters the heating state, and the temperature starts from room temperature The degree rises every secondAt a speed of 3 degrees (slope value of 3 degrees per second), increase to 160 degrees (preheating section temperature setting), maintain atMaintain a constant temperature of 160 degrees for 30 seconds (set value for preheating period), at which point the "preheating period" work process is completed Heating is included in the next paragraphThe working process of the insulation section. The lower heating starts from room temperature after starting the heating process, and the temperature is set at Rising in secondsAt a speed of 3 degrees (slope value of 3 degrees per second), increase to 160 degrees (preheating section temperature setting) and maintain at Maintain a constant temperature of 160 degrees for 30 seconds (set value for preheating period), at which point the "preheating period" work process is completed, and then add Hot enters the next sectionThe working process of the insulation section. Infrared preheating: Set 210 ℃ to indicate that the infrared heating plate is activated Heat up toConstant at 210 ℃.

(2)Insulation section (second section): Heating the upper part according to the slope3 degrees per second, rising from 160 degrees to 190 degrees, and then maintaining a constant temperature 30 seconds.

Heating the lower part according to the slope3 degrees per second, rise from 160 degrees to 190 degrees, and then maintain a constant temperature for 30 seconds.

(3)Heating stage (three stages): Heating the upper part according to the slope value3 degrees per second, rising from 190 degrees to 225 degrees and then remaining constant Wen30 seconds.

Heating stage (three stages): Heating the upper part according to the slope value3 degrees per second, rising from 190 degrees to 225 degrees and then remaining constant Wen30 seconds.

(4) Weld section 1 (four sections), weld section 2 (five sections), and control the cooling section (six sections) as above. The actual temperature of this system The number of control process segments can be less than the maximum number of control segments in the system(Section 8), control not required for actual heating process The end can set the corresponding parameters of the segment as0 is blocked.

7useCoolay touch screen all-in-one machineofBGA rework station:

The high-resolution image of the seven inch touchscreen all-in-one machine is clear,The A8 processor runs more smoothly.